When performing service work or installing Subaru’s accessory short-throw shifter, it’s extremely important that the transmission is supported properly when removing or reinstalling the crossmember. If not, damage to the bolts and/or threads will occur.

Support the transmission using a transmission jack, regardless if the vehicle is supported by a lift or car ramps. It’s recommended that hand tools be used for the removal and installation of the bolts. Inspect for bolt thread damage and replace as necessary. Be sure to clean any protective wax from the mating surfaces and to start all bolts several threads by hand before using tightening tools.Note: If severe damage is evident to the threads, the use of a Heli-coil type kit is an approved repair method.

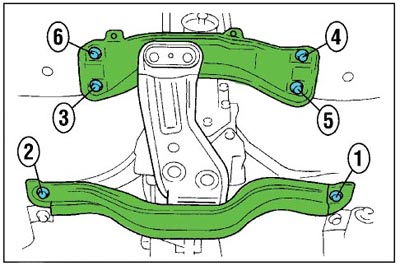

During reinstallation, use the torque sequence shown in Fig. 1

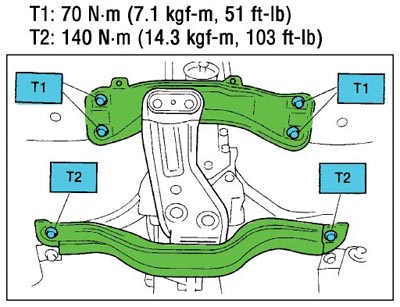

and the torque specifications shown in Fig. 2. Note: Bolts must be torqued to the proper specifications.

Technical service bulletin courtesy of ALLDATA.

For additional information, visit www.alldata.com.