CC:

Any brake pad manufacturer can claim their brake pads are quiet, but you have to ask, compared to what and who did the testing? The gold standard of brake noise testing is the Society of Automotive Engineers J2521. The procedure detects and records high frequency noise occurrences for vehicles with a gross vehicle weight below 10,000 pounds. A human test driver does not perform the test. Instead, it is performed on a brake dynamometer that can simulate more than 3,000 stops in a short period. A brake dynamometer can simulate a vehicle’s speed, weight and inertia while braking. It can do this using powerful electric motors and heavy discs.

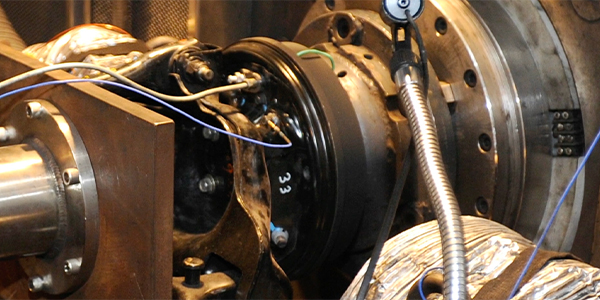

J2521 uses just one corner or axle of the vehicle. The engineers will mount the knuckle, wheel bearing, rotor and caliper to a fixture connected to the dynamometer’s output side. The fixture is placed inside an environmental test chamber that can quickly change the weather. The dynamometer will simulate more than 3,000 stops during a J2125 test under varying speed, temperature, and even humidity conditions.

Inside the test chamber is a calibrated microphone that measures the decibel level and frequency of a brake noise incident. Since the test is carried out using a computer, there is little possibility of human influence or error. Vehicle engineers use this procedure to get an apples to apples comparison of brakes. A J2521 test report will log all of the incidents of noise and classify them by frequency and sound pressure for a given test condition.

When you see a claim like a percentage of stops below 90 decibels, this data came from a J2521 test. With these tests, less is better. In this chart, we can see that this Akebono pro act application had fewer noise incidents than the competition. J2521 gives a brake pad manufacturer the ability to back up claims that their brake pads are quiet, which is much better than the opinion of the marketing department.

This video is sponsored by Akebono Brakes.