If a 1999.5-2001 Pathfinder exhibits a squeak/creak noise at the right-hand rear shock area while driving, a small stone, rock or pebble may have become lodged between the upper eyebolt of the right-hand rear shock and its mounting bracket.

It’s also possible for a small rock, pebble or stone (dia. 15-20 mm) to become trapped in this area and then fall out over time. This would make the incident seem intermittent to the customer.

Use this service procedure to inspect for, confirm and then resolve the incident, if it has occurred.

Service Procedure: 1. Remove the right-hand rear wheel.

1. Remove the right-hand rear wheel.

2. Remove the upper bolt from the shock absorber (nut=17 mm, bolt head=19 mm).

3. Remove the shock absorber from the upper bracket.

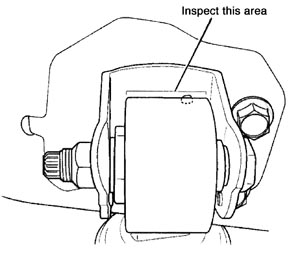

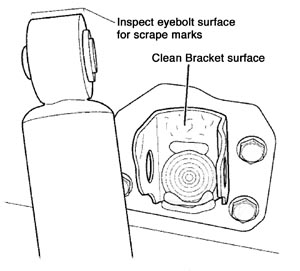

4. Inspect for scrape marks on the painted surface of the eyebolt. This will indicate a rock or pebble was trapped and rubbing in this area. See Fig. 1.

5. Clean the surface of the upper bracket with a shop rag. See Fig. 2.

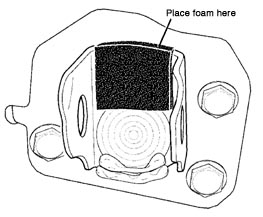

6. Cut a piece of foam (P/N 73982-4L700) to 30×30 mm (1-1/4” x 1-1/4”).

7. Place the foam inside the upper bracket near the top where the eyebolt installs. See Fig. 3.

8. Reinstall the shock to the upper bracket.

9. Reinstall the nut and bolt to the shock absorber. Bolt torque: 67-88 Nm (6.8 – 7.0 kg-m 49-65 ft.-lb.).

10. Reinstall the RH wheel. Wheel nut torque: 118 – 147 Nm (12 – 15 kg-m, 87 – 108 ft.-lb.).

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.