Customers with a 2003 Murano (Z50) built before Dec. 13, 2002, may complain of a metallic knock/clunk noise from the rear of the vehicle, especially during cold ambient temperatures, when driving over large bumps and/or driving on rough surfaces.

Customers with a 2003 Murano (Z50) built before Dec. 13, 2002, may complain of a metallic knock/clunk noise from the rear of the vehicle, especially during cold ambient temperatures, when driving over large bumps and/or driving on rough surfaces.

Use chassis ears to see if the noise is coming from the rear shock upper mounting bracket(s). If confirmed, continue with the Service Procedure. If you can’t confirm the noise, this bulletin does not apply. Look for other causes of the noise.

Service Procedure:

Modify the rear shock upper mounting bracket seals as follows:

1. Remove the rear shock upper mounting brackets. Refer to the RSU section of the applicable electronic service manual.

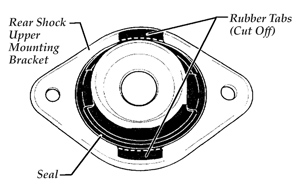

2. Cut off both rubber tabs from the rear shock upper mounting brackets. See Fig. 1.

3. Reinstall the rear shock upper mounting brackets in the reverse order that they were removed.

4. Road-test the vehicle to confirm the incident noise is gone.

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.