APPLICATION

GM power steering gears: 27-6535, 6560, 7525, 7547, 7549, 7561, 7562,7563, 7573 and 7583.

PROBLEM

Crunch and/or popping sound during low-speed turning.

CAUSE

The lower control arm may be striking the steering knuckle during full-turn type maneuvers, causing the crunch sound. Slight movement between the steering gear attaching bolt threads and the frame rail inboard steering gear attaching holes may cause the popping sound.

SOLUTION

Crunch Sound: Applying a light coat of grease on the control arm and knuckle where contact is made should reduce the noise.

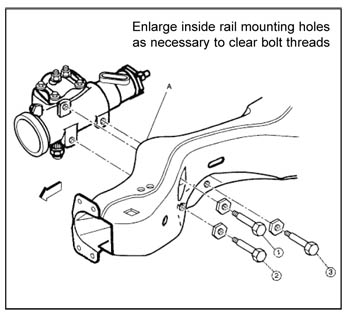

Popping Sound: Examine the frame rail inboard steering gear attaching holes for evidence of bolt thread contact. Enlarge inboard mounting holes that show contact only enough to allow the bolt threads to be free in the frame holes (use appropriate tools for the job). Reinstall the gear, but do not tighten bolts 1, 2 and 3 (see figure 1). Then perform the following steps:

Popping Sound: Examine the frame rail inboard steering gear attaching holes for evidence of bolt thread contact. Enlarge inboard mounting holes that show contact only enough to allow the bolt threads to be free in the frame holes (use appropriate tools for the job). Reinstall the gear, but do not tighten bolts 1, 2 and 3 (see figure 1). Then perform the following steps:

1. Start the vehicle and cycle the steering lock to lock several times, allowing the gear to reposition itself.

2. Torque attaching bolts (1, 2 and 3) to 70 ft. lbs. (95 Nm).

Please refer to the vehicle service manual for detailed gear removal and installation procedures.

Note: This Pro Tech bulletin is supplied as technical information only and is not an authorization for repair.

Tech Tip courtesy of CARDONE.

For additional information on products offered by CARDONE, visit www.cardone.com.