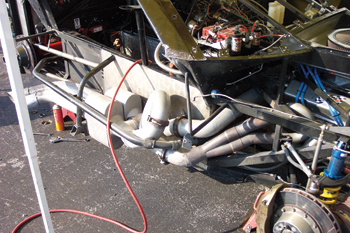

Custom exhaust work is one of the first modifications an owner may perform. It can help the car or truck breath better and make more power. But, often some vehicles do not have a performance system available because the vehicle is to new, rare or the owner wants something special.

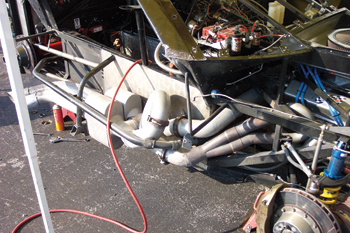

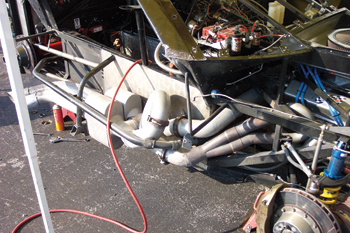

To give the customer what they want, you might have to fabricate the system. Before you start looking for the largest tubing that will fit, you must first do your homework if you intend to customize both gas and diesel vehicles.

Gas Temperatures

As the exhaust gases exit the exhaust valve, they are cooling down. As they cool, the gases contract and take up less volume. This can create a vacuum that can help scavenge or pull exhaust gases from another cylinder. Also, as a gas is compressed, it will heat. The modern exhaust system is designed around these three principles.

How well an exhaust system is able to manage temperatures and volumes can determine the overall performance and emissions. If an exhaust system is restrictive, it might hinder power production and raise exhaust gas temperatures. If the system flows too freely, exhaust gas temperatures might not reach high enough temperatures to burn raw hydrocarbons in the converters or soot in particulate filters.

If a replacement exhaust system does not meet or exceed the flow characteristics of the original system, it could mean more than a loss of power. This is where a properly bent and fabricated replacement system made of the right materials can make all the difference.

Materials

Most modern OE exhaust systems and aftermarket systems use stainless steel. Stainless steel prevents corrosion and oxidation under high temperatures. But, it can be more brittle than aluminized steel. But, both materials have their place in an exhaust system.

Design

If you intend to redesign the system from the exhaust ports back on some late-model vehicles, it takes more than just the tubing. It requires modification of the fuel trim. This may involve remapping the ECM, replacement of injectors and maybe changes to the sensors. This is true for gas and diesel vehicles.

If you are replacing a system on a late-model diesel vehicle, the new system has to have the right back pressure and be able to withstand the heat of the regeneration process that burns the soot trapped in the filter.

Bends

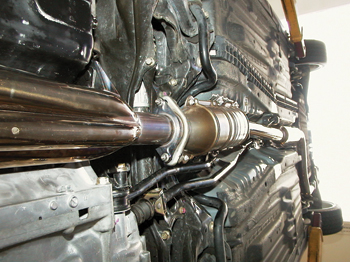

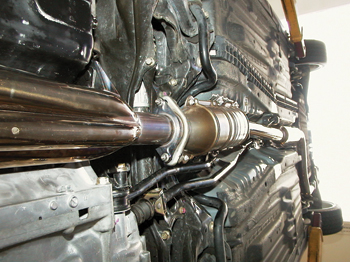

The first sign of a high-quality system is the bends. Expensive and well-made systems use mandrel bends. This type of bend uses special dies on the inside and outside of the tubing to ensure the internal diameter of the does not change.

Often, these bends require the use of a machine that is computer controlled.

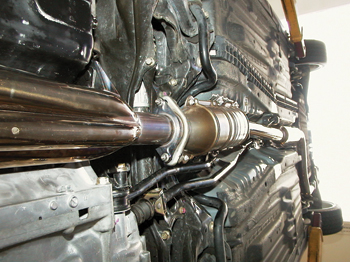

Coupling and Mounting

Exhaust systems are subjected to resonance and vibration that can lead to cracking and damage. Also, movement in the chassis and engine can cause a system to fail. A well-engineered system will use the right connections at the right point.

Even the strongest of welds and brackets will fail if the system does not have the right couplings. High-quality flex sections and slide joints do not create restrictions if used properly.

2008 model year vehicles (light- and medium-duty gas and diesel) went on sale almost five years ago. Some of these vehicles have gone more than 50,000 miles and are no longer covered under the manufacturers’ warranties. This is also the year that many vehicles had some of the most sensitive parameters for fuel trim. Also, all medium-duty diesel vehicles were fitted with exhaust particulate filters. Some of these systems are starting to leak or the flex couplings are wearing out.

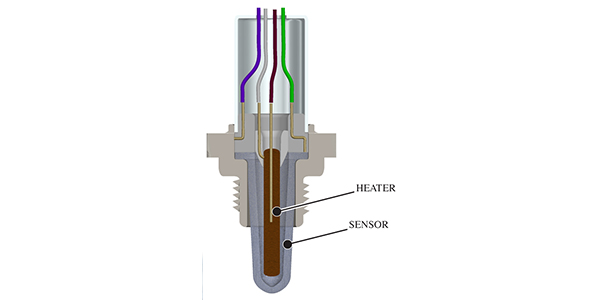

Bungs and Sensors

If you are dealing with oxygen sensors and thermocouples, the location is critical for their operation. If an oxygen sensor is to far from or to close to the exhaust port or catalyst, it could affect the readings and calibration of the sensor.