CC:

Clint Cooper:

Hi, I’m Clint Cooper, the emissions technology expert at AP Emissions. I’m here with Ryan McDonough, our manufacturing and product expert, to discuss manufacturing process.

Ryan, I’ve got some questions for you. Most of the time I’m out in the field doing sales or technical training. What I’d like to know is how we go about producing so many parts?

In our last video, we talked about how we go about prototyping those parts. But now let’s talk about production. So what’s the first step? Once we’ve come up with that jig, we’ve got our fixture. How do we go about producing these parts in volume?

Ryan McDonough:

There’s thousands of components that go into these things. So the first step is gathering the right components to make the part that you’re trying to make. Rather than have a welder, in their work cell, weld a part on a single jig on a stationary table, we have multiple jigs on a carousel table that rotates in and out of their work cell. So you don’t need to wait for the part to cool down, or a fixture to be picked up and moved into place.

Clint Cooper:

Nice. So the welders can focus on welding while the separate assembler puts the parts in the fixture. So we’ve got a catalog of a bunch of bended elbows at 45 degrees and 35 degrees and some flanges and straight tubes of various lengths, right. And so when we go to develop that part, that part has a bill of materials that calls out those specific parts that have to be put into that fixture. Is that the way it goes?

Ryan McDonough:

That’s exactly right.

Clint Cooper:

Okay. How many fixtures do we have? How many can we make up simultaneously for a typical part?

Ryan McDonough:

So overall, we probably have two, three, 4,000 fixtures.

Clint Cooper:

Wow, that’s a ton.

Ryan McDonough:

How many parts? Well, we have three facilities in Goldsboro, North Carolina, Langhorne, Pennsylvania, and Hobart, Indiana. So between the three facilities, we are producing upwards of 150 part numbers at the same time.

Clint Cooper:

At the same time. So simultaneously we could be cranking out 150 catalytic converters simultaneously?

Ryan McDonough:

That’s correct.

Clint Cooper:

That’s amazing. So when we’re doing a run, are we usually simultaneously manufacturing lots of different parts at the same time, or are we usually just focusing on one part and major volume for that one part?

Ryan McDonough:

We’re making many different parts at the same time. For example, in the Langhorne facility, we have upwards of 40 welders. All could be making a different part and mass quantities of each part.

Clint Cooper:

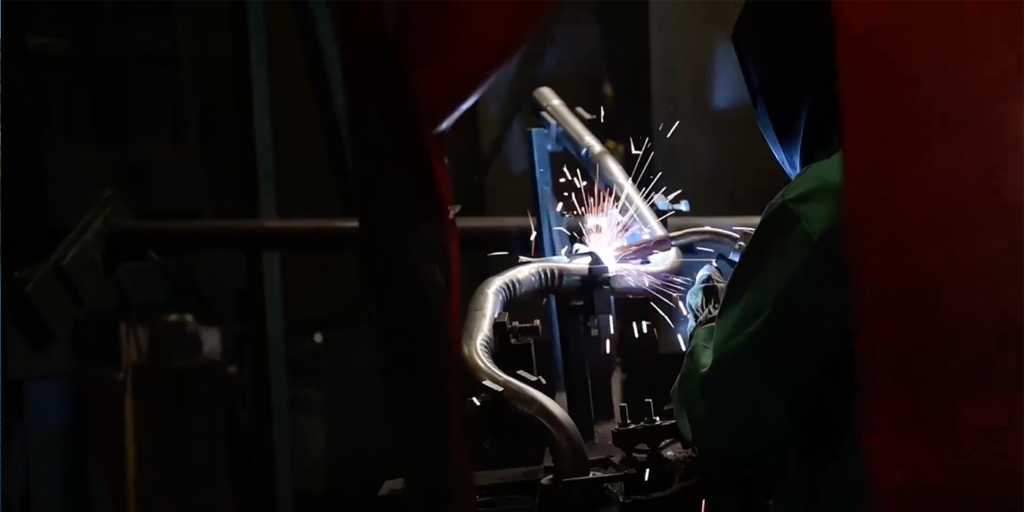

Okay. So this isn’t like robots and big robotic arms welding this stuff. These are people in welding booths and creating these parts individually from the jigs that we’ve created?

Ryan McDonough:

That’s correct. These are welding experts and craftsmen.

Clint Cooper:

Great. Do the welders put the individual components into those jigs, or does somebody else do that?

Ryan McDonough:

That’s a great question. So old school, yes, the welder would set the part up for himself and weld it. These days we’ve introduced our carousel system where there’s a support person who helps the welder get the components in the fixtures, so the welder can weld.

Clint Cooper:

So somebody goes out, they get the components, they lock them into the fixture, and then spin that carousel into the welding booth where the welder just focuses on welding. That’s right. They’re done welding, they spin it out and the next part just comes right in, right?

Ryan McDonough:

Gives the time to cool down and a quality check.

Clint Cooper:

That’s important. The time for it to cool down. A lot of times that stainless steel wants to bend back to its original shape, so you need to leave it in that jig for a nice long time, so it stays in the shape it’s supposed to be. Right?

Ryan McDonough:

That, coupled with our welders experience and their knowledge of how to weld a part the correct way, helps with keeping that part in the fixture.

Clint Cooper:

Correct. So you mentioned quality control. How do we check the quality of our parts?

Ryan McDonough:

So we can check the quality a bunch of ways. In our fixtures, against the OE that we have. We have master samples, and also our fit check photos also help.

Clint Cooper:

So put a QC stamp on it, once it’s produced. Once we checked to make sure that it’s accurate and then we box it up and put it on our shelves.

Ryan McDonough:

Don’t forget the bag of parts.

Clint Cooper:

Oh, the bag of parts. Absolutely. So all of our conversions are going to come with the gaskets and the bolts needed to install that part. So when the cars on the lift, you don’t have to worry about, do I have this gasket or anything else? This comes in the box, right?

Ryan McDonough:

That’s correct, Clinton.

Clint Cooper:

Great. Is there anything else to talk about manufacturing, or is that pretty much it?

Ryan McDonough:

I think that sums it up, Clint.

Clint Cooper:

Excellent. In this video, we’ve talked about our manufacturing procedures, how we go out manufacturing that part, and doing a production run. In our previous video, we talked about how we prototype parts. In our next video, we’re going to be talking about an important topic to everybody, and that is catalytic converter theft. Thanks for watching.

This video is sponsored by AP Emissions