VIDEO: ABS Pressure Transducer Diagnosis

Jason Stahl discusses the function of pressure transducers, and how its failure can affect the ABS system, including the HCU. Sponsored by Standard.

VIDEO: Low Pedal Condition On High Performance Vehicles

Andrew Markel discusses high performance vehicles, and how a low pedal condition could come from bearing performance. Sponsored by BCA Bearings.

VIDEO: Common TPMS Relearn Mistakes

Jason Stahl goes over some common mistakes made during a TPMS relearn, and how to prevent them. Sponsored by Standard.

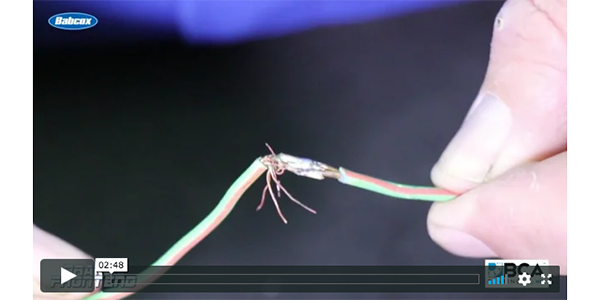

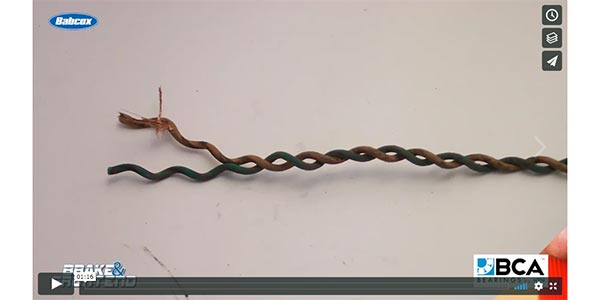

VIDEO: Wheel Speed Sensor Harness Repair And Electron Flow

Andrew Markel follows up on a previous video on wheel speed sensor harness repair, focusing on how voltage and electricity flow through the harness and how a splice may not last forever. Sponsored by BCA Bearings.

VIDEO: The Technology Of Bearing Grease

Andrew Markel discusses wheel bearing grease, and how it has been developed to keep rolling elements moving with maximum efficiency and minimum friction. Sponsored by BCA Bearings.

VIDEO: Don’t Try To Repair A Wheel Speed Sensor Harness

Andrew Markel discusses wheel speed sensors, and how a repair should generally not be attempted on its wiring. Sponsored by BCA Bearings.

VIDEO: Diesel Particulate Filters And Regeneration Cycles

Jason Stahl discusses diesel fuel systems, and the ideal time to perform a regeneration cycle, if the vehicle is able to perform the procedure. Sponsored by Standard.

VIDEO: How Brake Calipers Equalize Brake Pressure

Andrew Markel discusses brake calipers and how the guides and slides equalize pressure during brake operation. Sponsored by MEYLE.

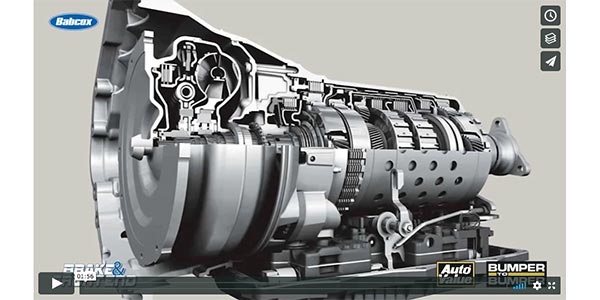

VIDEO: Testing The Transmission With The Stall Test

Andrew Markel introduces two mechanical tests that can be performed on a transmission to gauge its road performance. Sponsored by Auto Value and Bumper to Bumper.

VIDEO: How Rotor Metallurgy Affects Braking Performance

Andrew Markel discusses how the physical makeup of brake rotors can be different between products, and how braking performance can be affected by the quality of materials. Sponsored by MEYLE.

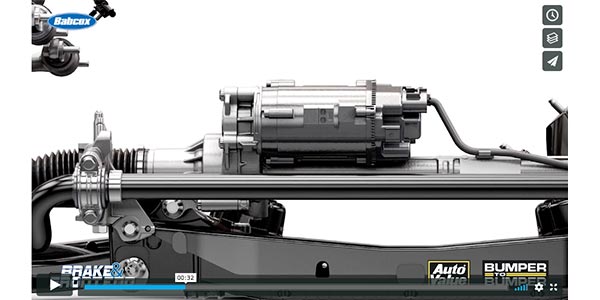

VIDEO: Power Steering ECM Technology

Andrew Markel discusses power steering systems, and how it uses sensors and the ECM to add steering assist during certain road conditions. Sponsored by Auto Value and Bumper to Bumper.

WATCH: TTY Bolts For Suspension And Brake Components (Torque + Angle)

In this Tech Minute, Andrew Markel covers everything about TTY bolts and how their build could affect your next suspension repair. Brought to you by MEYLE.