Why do the torque specifications for the axle nut vary so much from vehicle to vehicle?

This is a difficult question to answer because not all applications are the same.

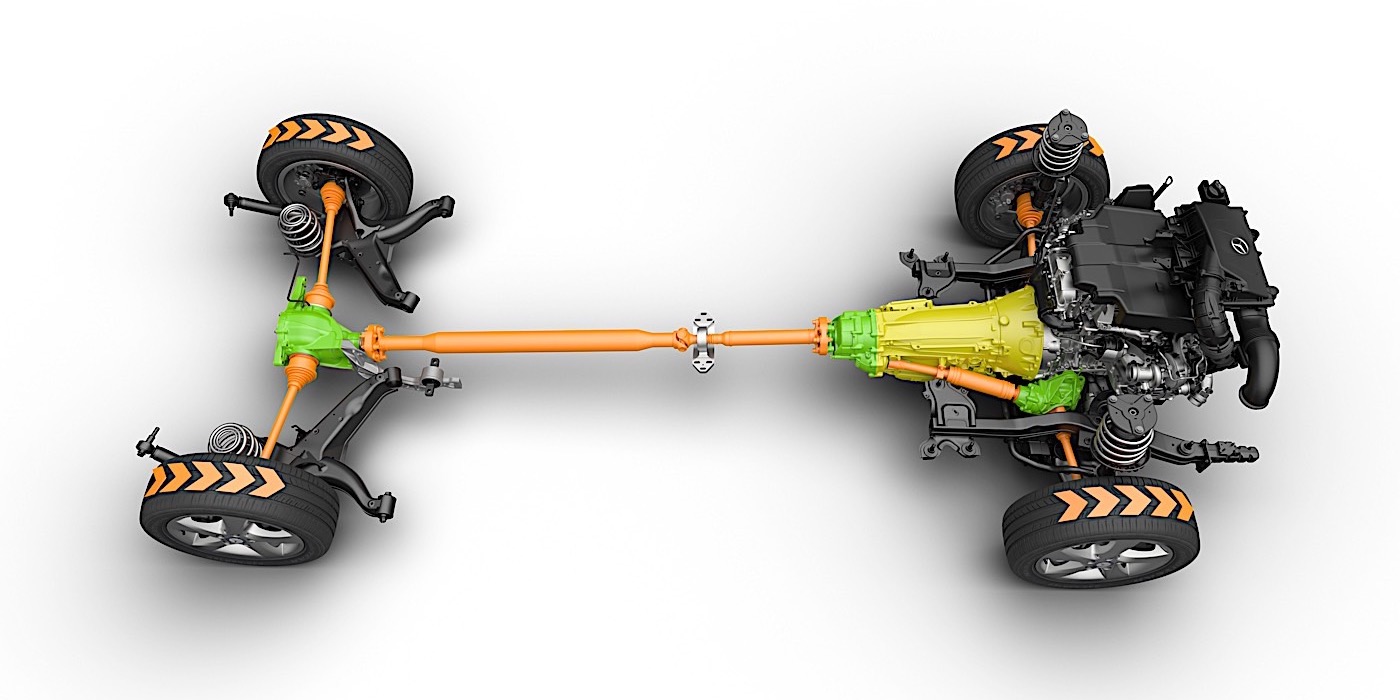

On some wheel bearings sets and hub units, the axle nut secures the outer flange to a CV joint or stub axle. As the nut is tightened, it pulls the flange and axle together to set the preload of bearings. These axle nuts will have specifications as low as 130-foot pounds and as high as 300-foot pounds.

If the preload is set at the factory with orbital forming or other processes, the nut holds just the axle in the splines and to the flange. With these types of units, they will have lower axle nut torque specifications between 85- and 170-foot pounds.

The torque specification can also vary according to the size of the rolling elements. Also, the type of axle nut influences the torque specification.

The bottom line is that there are so many variables in wheel bearing design and application that one torque specification for axle nut torque is impossible.

This is why, BCA includes the “Axle Nut Torque Specification Booklet” in the box with applicable wheel hub assemblies. The pocket-sized publication has 68 pages of front and rear axle nut specifications covering Acura to Yugo and everything in between! The booklet also has nine pages of notes covering model-specific torque procedures and information if the nut can be reused.

This video is sponsored by BCA Bearings by NTN.