A Honda Civic owner may complain of a rattle from the A-pillar trim or the dashboard corner area when driving on a rough or bumpy road. The probable cause for this condition is too much clearance between the A-pillar trim and the dashboard. Eliminate the noise by applying wool felt to the A-pillar trim, as described in this tech tip.

Required Materials:

• Wool Felt (100 mm x 1,000 mm), P/N 06993-5A5-000.

• Wool Felt (100 mm x 1,000 mm), P/N 06993-5A5-000.

Note: One piece is enough to repair eight to 10 A-pillar trim pieces.

Diagnosis:

Test-drive the vehicle on a rough or bumpy road, and listen for a rattle. If a rattle comes from the lower A-pillar trim area (driver’s side, passenger’s side or both), apply pressure to the trim.

• If the rattle goes away, proceed with the Repair Procedure.

• If the rattle goes away, proceed with the Repair Procedure.

• If the rattle continues, look for other causes.

Repair Procedure:

1. Remove the front door opening trim near the affected A-pillar trim. See

Fig. 1.

2. Remove the A-pillar trim by releasing the two clips.

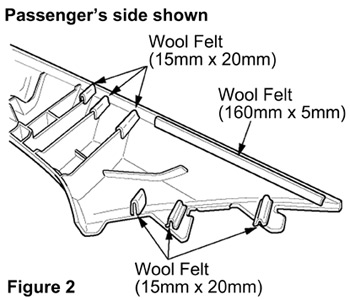

3. Cut six 15 mm x 20 mm pieces of the wool felt, remove the adhesive backing, and install the felt onto the A-pillar trim ribs in the areas shown in Fig. 2.

4. Cut one 160 mm x 5 mm piece of the wool felt, remove the adhesive backing and install the felt onto the A-pillar as shown in Fig. 2.

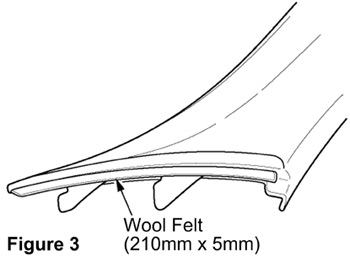

5. Cut one 210 mm x 5 mm piece of the wool felt, remove the adhesive backing and install the felt onto the A-pillar as shown in Fig. 3.

6. Reinstall the A-pillar trim and the front door opening trim.

7. Make sure the wool felt is not visible.

8. If the rattle was heard at both A-pillars, repeat steps 1 through 7 to repair the other side.

9. Test-drive the vehicle on the same rough road to check for the rattle.

• If the rattle is no longer present, the repair is complete.

•If the rattle is still present, look for other causes.

Written by Ed Dorowski, ALLDATA editor and Jeff Webster, ALLDATA technical writer.