While it’s important to handle any bearing with extreme care, SKF highly recommends following these specific procedures when cleaning bearings.

Cleaning Procedure:

1. To begin the cleaning process, soak the bearings in a metal basket suspended in a clean container or tank holding a recommended solvent soaking the bearings overnight, if possible. If a basket is not available, suspend the bearings with a wire, or place them on a metal plate at the bottom of the container.

Note: Do not rest the bearings directly on the bottom of the bucket (they may not clean as efficiently due to sediment on the bottom of the container).

2. After dirt and grease are removed, rinse the bearings in another clean bucket of solvent (See Fig. 1).

The bearings should then be thoroughly dried. The safest method is natural air-drying. Compressed air, which is free from condensed moisture, may be used to blow out the bearings, but only after all dirt and chips have been removed (See Fig. 2).

Note: If compressed air is used, do not allow bearings to spin and always wear safety glasses to protect your eyes from injury.

3. After cleaning, inspect the bearing thoroughly for nicks, leftover dirt and damage. Inspected bearings, which are considered “good” may be used again. However, if re-assembly cannot be done immediately, these bearings should be protected.

4. Dip the cleaned bearings in a protective lubricant, or coat all surfaces with a light grease (See Fig. 3).

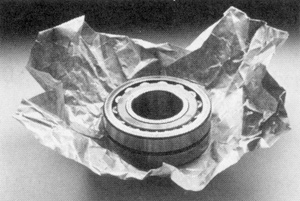

Rotate each bearing to work the grease thoroughly in and around the roller and on the races. Then wrap the bearings in waterproof paper and place each in a clean box or carton (See Fig. 4).

If cartons are not available, just wrap them in waterproof paper. Mark the outside of each package to identify the bearing enclosed.

Courtesy of SKF.