If a customer indicates that a light ticking or humming noise can be heard coming from the blower motor (see affected vehicles) when the motor is run at low fan speeds (speed 1 or 2), a noise-reducing blower motor is available. The noise may be very slight and, at times, difficult to hear.

Affected Vehicles:

• 1996-2001 Pathfinder (R50);

• 1995-’99 Maxima (A32);

• 2000-’01 Maxima (A33) with automatic heater/air conditioner controls.

Service Procedure:  1. Run the blower motor at low fan speed (speed 1 or 2) and evaluate the noise. Decide which category the noise falls under:

1. Run the blower motor at low fan speed (speed 1 or 2) and evaluate the noise. Decide which category the noise falls under:

- Loud rattle, clatter, jolt or flap: go to the procedure for blower case cleaning.

- Light ticking or humming noise: complete the following steps to install a new blower motor cover.

2. Remove the instrument panel lower cover (if equipped).

3. Disconnect the blower motor harness connector.  4. Clean the blower motor housing to ensure adhesive strips on the back of the blower motor cover will stick (standard window cleaner can be used).

4. Clean the blower motor housing to ensure adhesive strips on the back of the blower motor cover will stick (standard window cleaner can be used).

Note: Be sure to remove all residual film from the blower motor housing that may have been left by cleaning.

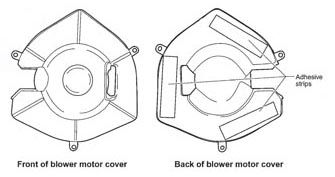

5. Peel the protective coverings from the adhesive strips on the blower motor cover. See Fig. 1.

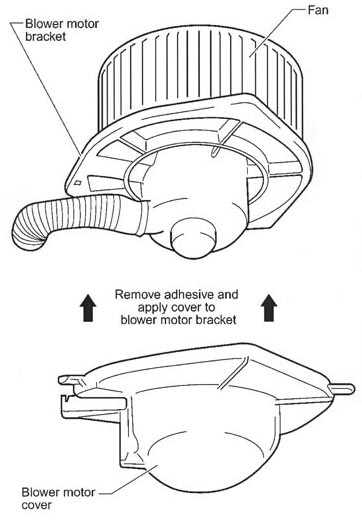

6. Install the blower motor cover onto the motor bracket. See Fig. 2.

7. Reconnect the blower motor harness connector.

8. Reattach the instrument panel lower cover (if equipped).

9. Run the blower motor at low fan speed. Confirm that the blower motor is working properly and the noise is eliminated or reduced to an acceptable level.

Blower Case Cleaning:

1. Remove the blower motor unit from the blower case.

2. Remove all foreign material from the case.

3. Reinstall the blower motor unit.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.