Vehicles:

2003-2004 Honda Civic 4-door EX ad LX — VIN starts with 1HG or 2HG.

Symptom:

At any fuel level, the fuel gauge reading drops by 1/4 tank, or three to four graduation marks. In some cases, the fuel gauge indicates “E” and the low fuel level warning light is on. After driving for several minutes, or cycling the ignition switch off/on, the fuel gauge returns to the correct reading. This problem is intermittent, and it affects only Civics with Visteon gauge assemblies.

Probable Cause:

The software specification for calculating the current fuel level is incorrect.

Corrective Action:

Replace the gauge assembly.

Repair Procedure:

1. Tilt the steering wheel all the way up.

2. Remove the three upper cover mounting screws from the lower steering column cover, then tilt the steering wheel all the way down, and remove the column covers.

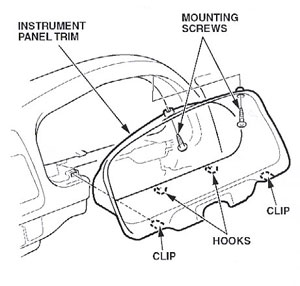

3. Remove the two mounting screws from the instrument panel trim. Gently pull on the bottom of the trim to release the two clips and the two hooks. Carefully pull the trim out of the dashboard.

4. Remove the three mounting screws from the gauge assembly, and gently pull it away from the dashboard. Unplug the blue and green 22P connectors from the top of the assembly, the remove the gauge assembly.

5. The install the appropriate new gauge assembly.

Note:

• Laws governing odeometer repair, replacement or servicing may vary from state to state. Questions concerning state law should be directed to your applicable state agency, DMV office or an attorney.

• Refer to the Honda Service Operations Manual (Section 2.24) for warranty policies and procedures regarding odometer servicing and replacement.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.