The rear brake calipers on any Cooper or Cooper S produced up to August 2004 may stick and cause the wheel to slightly drag when turning. This can be seen when the vehicle is suspended on a lift and is more likely to occur on the right side than on the left side. The cause is residual handbrake braking torque from unfavorable routing of the handbrake cable. If this condition is noted, modify the curvature of the handbrake cable elbow.

Service Procedure:

Service Procedure:

1. Do not replace the handbrake cable or brake caliper.

2. Lift up the vehicle.

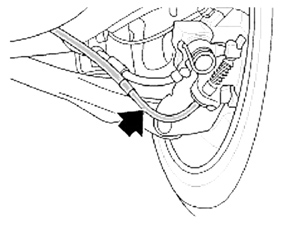

3. Slightly bend the handbrake cable elbow down to widen the angle (See arrow, Fig. 1).

4. Check to ensure free movement of the wheel (no binding or dragging when turning).

5. Repeat the bending of the elbow as necessary.

Note: Do not bend the handbrake cable elbow with excessive force.

Courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.