Rich Diegle

Senior Automotive Editor

Owners of 2003 Chevrolet Impala and Monte Carlo or Buick Regal and Century vehicles may comment on reduced power steering, excessive steering effort, rubbing or excessive noise in the passenger compartment. The cause of the problem may be due to the intermediate shaft lower boot between the bulkhead and the steering gear being incorrectly installed and interfering with the intermediate shaft. Follow the manufacturer’s Diagnosis and Service Procedure below to correct this condition.

Diagnosis and Service Procedure

Review safety procedures in ALLDATA Repair before beginning.

1. Lift the front wheels off the ground. Raise and support the vehicle.

1. Lift the front wheels off the ground. Raise and support the vehicle.

2. With the ignition switch on and the engine off, have an assistant turn the steering wheel from right to left.

3. Grasp the intermediate shaft boot with either hand and while the steering wheel is being rotated, there should be no contact felt between the intermediate shaft boot and the intermediate shaft.

- If contact is felt, inspect the lower intermediate shaft boot forproper installation and damage.

- If the boot is improperly installed with no damage to the boot, correctly reposition the boot.

- If the boot is improperly installed and damaged, continue with the next step.

CAUTION: The front wheels of the vehicle must be maintained in the straight ahead position and the steering column must be in the LOCK position before disconnecting the steering column or intermediate shaft. Failure to follow these procedures will cause improper alignment of some components during installation and result in damage to the SIR coil assembly.

4. Turn the ignition OFF and remove the key from the ignition lock cylinder in order to lock the steering column.

5. Raise the vehicle.

6. Remove the left front tire.

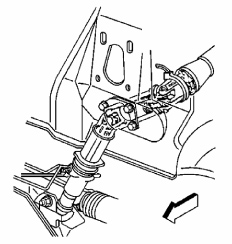

7. Position the boot in order to provide access to the lower pinch bolt on the intermediate steering shaft.

8. Remove the lower pinch bolt from the power steering gear stub shaft.

9. Remove the intermediate steering shaft from the power steering gear stub shaft.

10. Slide the damaged lower boot out of the upper boot and off the intermediate shaft.

11. Install the new lower intermediate shaft boot into the upper boot.

12. Position the intermediate steering shaft into place.

13. Install the lower pinch bolt to the intermediate steering shaft at the steering gear.

13. Install the lower pinch bolt to the intermediate steering shaft at the steering gear.

14. Tighten the pinch bolt to 48 N.m (35 lb ft).

15. Install the lower boot onto the steering gear.

16. Inspect to make sure the intermediate shaft is not contacting the boot.

17. Reinstall the left front tire.

18. Lower the vehicle.

19. Road test the vehicle to confirm the repair.

Written by ALLDATA Senior Automotive Editor, Rich Diegle. Rich is an Advanced Engine Performance Certified, ASE Master Technician with an AA Degree in automotive technology and 23 years of dealership and independent shop experience.

For additional information, visit www.alldata.com.