The original equipment belts on late-model vehicles are made of synthetic rubber that is far more durable, heat-resistant and wear-resistant than older materials. This means serpentine belts may last up to 100,000 miles or more before they have to be replaced, but that doesn’t mean they will last forever or won’t age prematurely on some vehicles under certain conditions. If you have a vehicle in your shop for belt replacement, diagnose why the belt needs to be replaced. Wear on a single component is rare and more than likely a worn tensioner, idler or pulley will cause or contribute to excessive belt wear — not just age. Also, decoupler pulleys wear out, causing excessive noise and a no-charge condition. This video is sponsored by Continental.

Flushing the Brake Fluid is Critical on Every Brake Repair

Making sure the brake fluid is the correct quality is critical. Sponsored by Auto Value and Bumper to Bumper.

Making sure the brake fluid is the correct quality for the vehicle and is not worn out is critical on every single brake repair. This video is sponsored by Auto Value and Bumper to Bumper.

Watch more IQ videos here: :

Selecting the Right Oil for your Customers Engine

Learn how to educate customers on the importance of OEM specifications and premium lubrication for their vehicles’ maintenance needs.

At the Intersection of Tradition and Innovation with Grace Hovis

Grace Hovis’s journey in Hovis Auto & Truck Supply blends tradition with digital innovation in the automotive aftermarket industry.

Matching OE Torque Specs When Reinstalling Is Important

Explore the key reasons as to why adhering to OE torque specs is crucial. This video is sponsored by TrakMotive.

Turbocharger Maintenance ft. Rein TechSelect Turbo Kits

Learn about common challenges with turbocharger maintenance and how Rein TechSelect Turbo Kitsmake the repair process easier for technicians.

Other Posts

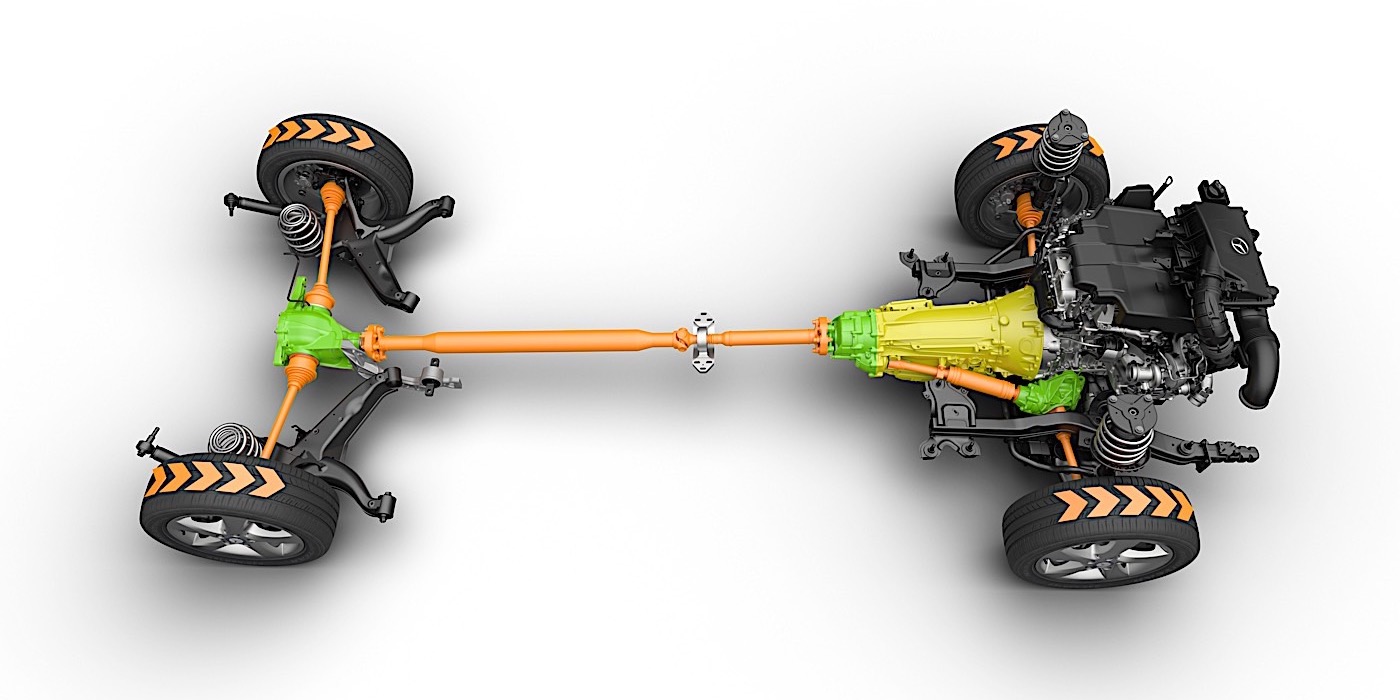

Diagnostic Test Drive For Drivetrain

A driveshaft center bearing can fail due to the bearing and the rubber isolator.

Continental Tire Opens Retread Solutions Center in South Carolina

The company said it hopes to uncover new improvements and technologies to innovate the retread process.

The Standard® Advantage

Standard® knows that what comes out of a repair is directly dependent upon what goes into the box. This video is sponsored by Standard®.

Tesla Model 3 TPMS Service

Resetting and programming TPMS sensors for a Tesla is a lot like any other vehicle, and the challenge is still the same: keeping the light off.