Bremskerl North America, a subsidiary of BREMSKERL REIBBELAGWERKE EMMERLING GMBH & CO. KG, a global manufacturer of friction material for rail, industrial and commercial vehicle markets since 1929, has introduced a fullline of air disc brake pads for the North American market.

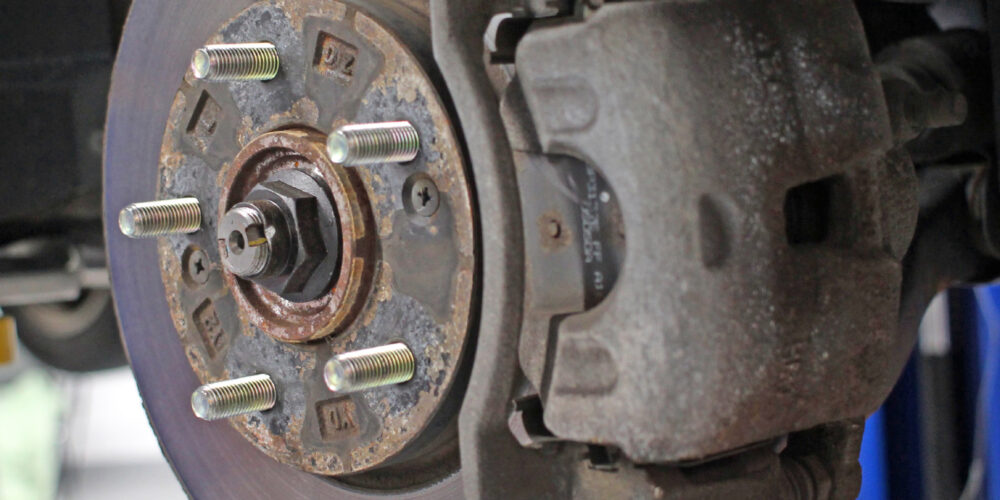

Bremskerl’s premium 8010 formulation is supplied at both the OE and aftermarket level and provides lower wear of the pad and disc rotor when compared with other OE and aftermarket manufacturers, the company claims. In addition, Bremskerl says the brake pad material is low-dusting, low-noise and provides excellent stopping performance. Bremskerl 8010 is currently in use on truck/trailer, transit, coach bus, fire truck and refuse applications.

Bremskerl’s premium 8010 formulation is supplied at both the OE and aftermarket level and provides lower wear of the pad and disc rotor when compared with other OE and aftermarket manufacturers, the company claims. In addition, Bremskerl says the brake pad material is low-dusting, low-noise and provides excellent stopping performance. Bremskerl 8010 is currently in use on truck/trailer, transit, coach bus, fire truck and refuse applications.

According to the company, the eco-friendly brake pads contain less than 5 percent copper content, meeting new legislative requirements in both Washington State and California. They are also 100 percent asbestos-free and are RoHS- and REACH-compliant, which are key chemical and safety regulations in Europe.

Bremskerl’s air disc brake pad program includes 20 SKUs covering brake systems produced both domestically and abroad. The full line of Bremskerl disc brake pads is stocked at the company’s Illinois warehouse and available from distributors in the U.S. and Canada.

To download the BREMSKERL air disc brake pad flyer visit: http://files.bremskerl.de/USA/Bremskerl8010.pdf.