ACDelco is adding a proprietary surface coating to its police brake pads that the company says helps reduce the break-in period and improves pre-burnish brake effectiveness. The coating, designed specifically for police applications, is suitable for both patrol and high-speed-pursuit situations, according to ACDelco.

ACDelco police brake pads are long-lasting, feature quiet operation, are extensively tested and are in use by police agencies throughout the U.S., the company says. The new coated pads provide coverage for Chevrolet Caprice, Impala and Tahoe; Ford Crown Victoria and Interceptor*; and Dodge Charger police vehicles.

“We realize that instant responses may be required in pursuit situations immediately after a brake pad installation,” said Matt Gibbard, ACDelco brake product specialist. “That is why ACDelco answers the call with a proprietary coating that improves the braking performance of new pads.”

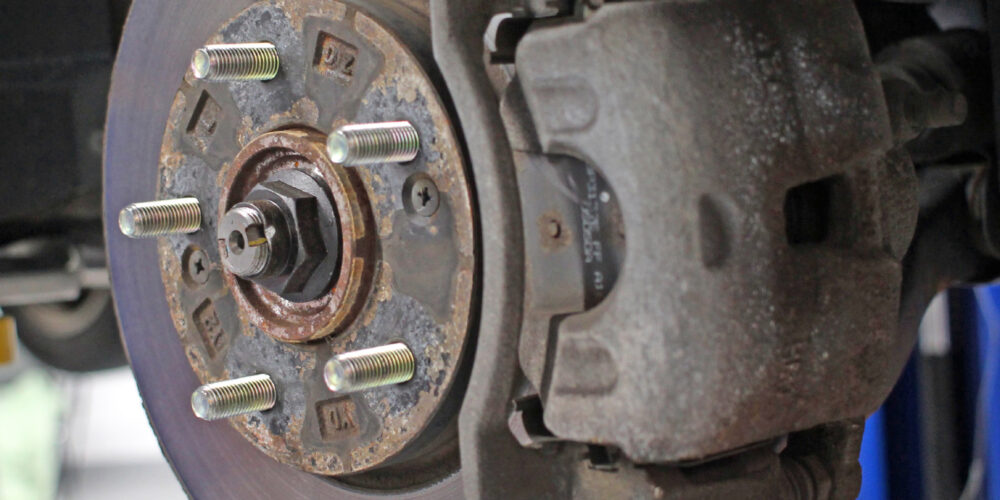

When replacing brake pads, a “break-in” or “burnishing” procedure is recommended to properly condition both the brake pads and brake rotors for optimum performance and brake life. The ACDelco coating is applied to the friction surface during manufacturing using a highly controlled process to ensure uniform coverage and applied density. Using ACDelco brake pads with the new coating does not change previously published in-use burnishing recommendations, but the coating significantly increases effectiveness during initial braking as well as throughout the life of the pad, ACDelco says.

The coating may temporarily release visible airborne gasses as it transfers material onto the brake rotor during the burnish procedure.

*New product release estimated December 2012

To find an ACDelco parts retailer, visit acdelco.com or call 1-800-ACDelco.