Rich Diegle

Rich Diegle

Senior Automotive Editor

You may get one of the Nissan vehicles listed below in the shop with engine oil accumulated on the engine block below the engine oil cooler area.

Inspect the engine, engine oil cooler and the oil cooler gasket for oil leakage. You may use a fluorescent oil dye leak detector to help more easily determine which component is leaking. If the oil is leaking from the oil cooler rubber gasket, replace the rubber gasket using the following manufacturer’s Service Procedure.

Vehicles:

2004-2006 Quest

2000-2006 Maxima

2003-2006 Murano

2002-2006 Altima with VQ35 engine only

Service Procedure:

Review safety procedures in ALLDATA Repair before beginning.

- Drain engine oil.

- Drain engine coolant. Do not spill coolant on the drive belt.

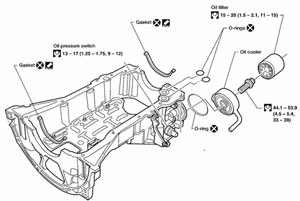

- Remove the oil filter and the oil cooler.

- Check oil cooler for cracks.

- Check oil cooler for clogging by blowing through coolant inlet. If necessary, replace oil cooler assembly.

- Inspect the oil pressure relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove valve by prying it out with a suitable tool. Install a new valve in place by tapping it.

- Installation is in reverse order of removal.

- When installing the oil cooler, install a new rubber gasket and align the oil cooler stopper with the stopper of the oil pan.

- Start engine and check there are no leaks of engine oil or coolant.

Written by ALLDATA Senior Automotive Technical Editor, Rich Diegle. Rich is an Advanced Engine Performance Certified, ASE Master Technician with an AA Degree in automotive technology and 23 years of dealership and independent shop experience.

Courtesy of ALLDATA.

For information on products offered by ALLDATA, visit www.alldata.com.