The most important part of the alignment process is the customer interview. Find out why they need an alignment. Ask them if they are experiencing any clunks, thumps or pops. Also, ask at what speeds they are experiencing the problem.

The most important part of the alignment process is the customer interview. Find out why they need an alignment. Ask them if they are experiencing any clunks, thumps or pops. Also, ask at what speeds they are experiencing the problem.

Pre-Alignment Inspection

The 2006-current Impala has been for the most part trouble free, but the steering system, including the linkage and power assist system, has been the topic of several TSBs. If the rack has been replaced or there is a customer complaint of noise or clunks, take the time to check the TSBs for proper diagnostic procedures.

The first items to inspect are the tires. Make sure to match the tire pressures that are listed on the driver’s side door pillar. Inspect the overall condition of the tires. If the customer is complaining the vehicle is pulling, take the time to mark the original position of the tires before rotation or radial force measurement procedures.

It has been reported by several law enforcement agencies and bearing manufacturers that the stock front-wheel bearings have a limited life if the driver is aggressive. Make sure to inspect the bearings before you perform an alignment.

Front Suspension

Front Suspension

Adjusting the camber requires some extra work, GM did not elongate the lower bolt holes that attach the strut to the knuckle on some vehicles or build adjustability into the upper strut mount. The 2010 documentation shows movement without requiring slotting.

Before performing the alignment, inspect any vehicle to find out if the alignment angles are adjustable or require extra parts, special procedures or kits.

If you rationalize that you can “eat” the extra labor time to slot struts or to install cam bolts, in hopes that the next few alignments will be more profitable, you will be working for free more often than you think.

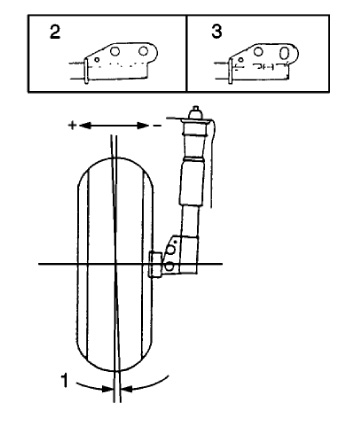

You can use two techniques to make the camber adjustable. First, you can file the lower bolt hole into a slot. GM recommends only performing this operation on the lower bolt hole. Typically, this can safely generate ±1.25º of camber adjustment.

Second, you can install a cam bolt in the upper strut-to-knuckle bolt hole. The aftermarket kits can give ±1.75º of adjustment. The strut-to-knuckle bolts should be tightened to 96 ft. lbs. Make sure the customer is charged for labor no matter what method is used.

There is no front caster adjustment on this vehicle. If the caster is out of specification, inspect the vehicle for damage to the lower control arm, bushings or the front cross-member.

Toe is adjusted with the tie rods. Make sure the bellows of the boot are aligned and the boot is in good condition. It has been reported that if the boot is misaligned or sagging, it can get caught on the inner tie-rod and bind up or cause a popping noise.

There are no special procedures to recalibrate the steering position sensor after the vehicle has been aligned. The calibration is performed by the computer when the vehicle is first driven.

Rear Suspension

The procedure to adjust the rear camber is to install cam bolts in the upper holes slots. The torque spec for the bolts is 89 ft. lbs.

The toe is adjusted with the rear adjustable lateral link.

TSB Checks

01-02-32-001P (Clunk While Turning): Some customers may comment on a clunk-type noise coming from the front of the vehicle while driving during a turning maneuver. This condition may also be felt through the steering wheel when the vehicle is stationary and the wheel is rotated from steering stop to steering stop.

Some vehicles may only exhibit the noise once for every 360° of wheel rotation. On all other vehicles, this clunk noise will be noticed during low speed acceleration or deceleration, typically in light turns of the steering wheel or when applying/releasing the brakes. This condition may be caused by a “slip stick” condition of the steering intermediate shaft resulting in the clunk noise or feel through the steering wheel. GM recommends replacing the shaft with an updated part.

07-03-09-001J (Creak, Pop, Clunk Noise, Rear Strut, Upper Mount): Some customers may comment on a creak, pop, or clunk noise coming from the rear of the vehicle. This condition may be caused by the rear strut spring rubber isolator contacting the lower spring coil. Through the rear wheelhouse opening, locate the lower first four rubber isolator tabs. Using an utility knife, cut the four tabs flush with the surface of the isolator. Be careful not to cut all the way through the rubber isolator to the metal spring coil. Apply a high-temperature water-resistant grease to the lower spring coil. Cover the entire area under the removed tabs.

Other Articles in this Series:

|

Suspension & Alignment Specs: 2007-2010 Dodge Caliber

The Dodge Caliber is a compact car produced by the Dodge division of Chrysler. The same basic platform is used for the Sebring, Avenger, Jeep Patriot/Compass and Mitsubishi Lancer. This is a "Net Build" vehicle with only toe adjustments built into the vehicle. Some adjustments for caster and camber can be made by moving the sub-frames. More

|

|

Alignment & Suspension Specs: 2006-2010 Honda Civic

Built on a high-rigidity unit-body platform, the 2006-current Civic has a MacPherson strut front suspension and multi-link rear suspension. The 8th-generation Civic switched from a high mounted steering rack to a low mounted one and significantly increased caster. In the alignment bay, the 8th-generation Civic does not hold any surprises. But, it does require a sharp eye to spot potential problems… More

|