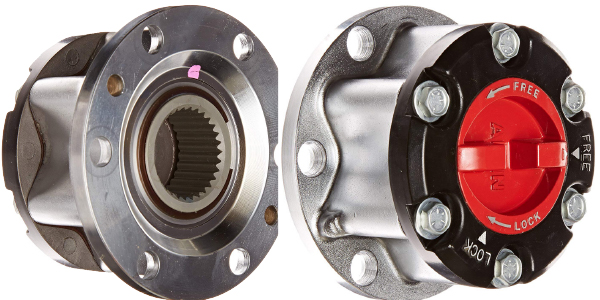

Automatic hubs are used on many 4×4 trucks to disengage the front wheels when four-wheel drive is not needed. The main advantage of being able to disengage the front wheels on the go is that the driver doesn’t have to stop, get out of the vehicle and twist a dial on the hub to disengage or engage the front wheels. The automatic hub does it automatically on the fly. The locking mechanism inside an automatic hub is sort of like a one-way clutch. When torque is applied by the driveshaft, it forces the hub to slide in and lock.

The hub then remains in the locked position as long as the transfer case remains in four-wheel drive. When the driver shifts to two-wheel drive, the clutch mechanism inside the hub slides back out and releases the hub, allowing the wheel to turn independent of its axle shaft.

There are a number of automatic hub designs and not all are capable of engaging while the vehicle is in motion. Some of the older types require the vehicle to stop and back up a short distance to engage the locking mechanism. Some automatic hubs don’t engage in reverse and others use a vacuum diaphragm to engage the hub (or the axle shaft) when switching between two- and four-wheel-drive modes.

HUB PROBLEMS

The driver may not notice anything is wrong until he finds himself stuck axle-deep in mud and realizes the front wheels aren’t doing anything. Or, you may hear some grinding noises when he shifts to four-wheel drive and may think something is wrong with the transfer case or front differential.

For the same reasons that prevent the hub from engaging, a hub may also fail to release. Anything that binds the internal mechanism can prevent it from sliding and releasing. The most noticeable symptoms may be an increase in fuel consumption, noise on the highway and/or increased front tire wear.

DIAGNOSIS

Diagnosing an automatic hub problem may require test driving the vehicle or raising a front wheel to see if the hub is engaging and disengaging properly. Put the transmission in park, set the parking brake and raise the chassis so one of the front wheels is off the ground while the other is still on the ground. When the transfer case is in two-wheel drive, the hubs should be released, allowing the wheels to turn freely when spun by hand. If the axle shaft turns when you spin the wheel, it means the hub has not disengaged.

To check engagement, rotate the axle shaft backwards. This should lock the hub. Try turning the wheel by hand again. The axle shaft should now turn with the wheel if the hub is locked. If the hub fails to lock, the hub will have to be disassembled and inspected or replaced.

To check release, hold the axle shaft steady and rotate the wheel backwards. You should hear a click as the locking mechanism slides back out and disengages the hub. Rotate the wheel forward again and it should turn freely.

Another way to check the hubs is to raise the vehicle on a frame contact lift so that all four wheels are off the ground. Then start the engine and place the transfer case in four-wheel drive and the transmission in drive. If the front wheels don’t turn, look at the front axle shafts. If both shafts are turning, but one wheel is not, the problem is a bad hub on the wheel that isn’t turning.