Wheel bearings and wheel speed sensors require precise tolerances to be kept under demanding conditions. For a bearing, loads on the races need to be controlled by the preload, so the wheel flange rotates in a near-perfect plane. For the wheel speed sensor, the relationship between the sensor and the tone ring needs a consistent air gap to determine the speed of the wheel. If the tone ring for the wheel speed sensor is mounted to the wheel bearing, the tolerances can become stacked.

If bearing has play, the air gap changes. If the air gap changes enough, the pattern produced by the sensor changes. When this happens, the ABS modulator processing the signals analyzes the abnormal patterns. If the module sees a dropout of the signal from the sensor, it would literally translate into the vehicle stopping in inches and then accelerating back to that speed in a few inches. The software controlling the ABS knows this is not possible, so it sets a code. These codes could have the word “erratic” or “malfunction” in the code description.

The change in the air gap can be caused by loads on the wheel bearing during a turn. To understand why active wheel speed sensors fail to report the correct speed of a wheel, it is necessary to understand what happens inside the bearing and the rolling elements, and how they change the relationship of the encoder ring and the sensor.

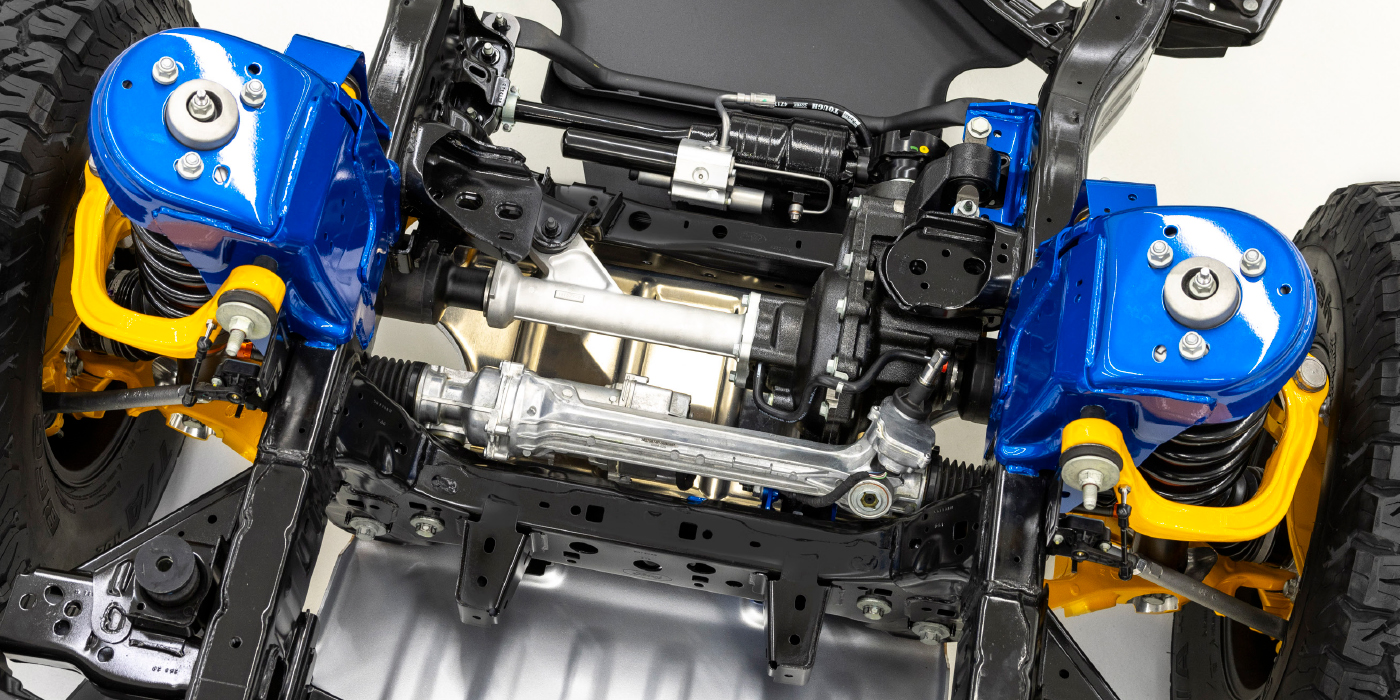

On a typical passenger vehicle weighing around 3,400 pounds, each pair of front-wheel bearings, as well as the rear-wheel or axle bearings, support around 850 pounds, depending on the weight balance and driveline configuration. If it’s a 6,000-pound SUV, each bearing might carry about 1,500 pounds. This load is concentrated on the relatively small bearing surfaces. Wheel bearing failures are event-related. Curb strikes, potholes and other incidents that may cause damage to the bearing surfaces and seals are what kill bearings, rather than an abundance of miles.

Scan Tools and Wheel Bearings

Scan tools have come a long way in the past decade, such that improvements in sample rates and display capabilities can give technicians vital insights into a wheel speed sensor and the wheel bearing.

A modern scan tool can graph the output of multiple wheel speed sensors on a test drive. The output is how the ABS control module sees the wheel speed sensors. On the test drive, take a corner to see how the speed changes between the inside wheel and outside wheel. If you see sudden drops in speed, it is a sign that the air gap between the encoder ring and sensor has changed due to play inside the bearing.

If you are looking for a new scan tool, wireless connectivity with the OBD II port can make wheel speed testing easier if you are working alone. With a vehicle on a lift, you can observe wheel speed sensor data as you spin a wheel.

Scoping Wheel Bearings

Using an oscilloscope or scope can measure more than just the output of the signal. Testing with a scope can show the health of the circuit with the wheel speed sensor on one end and the module at the other.

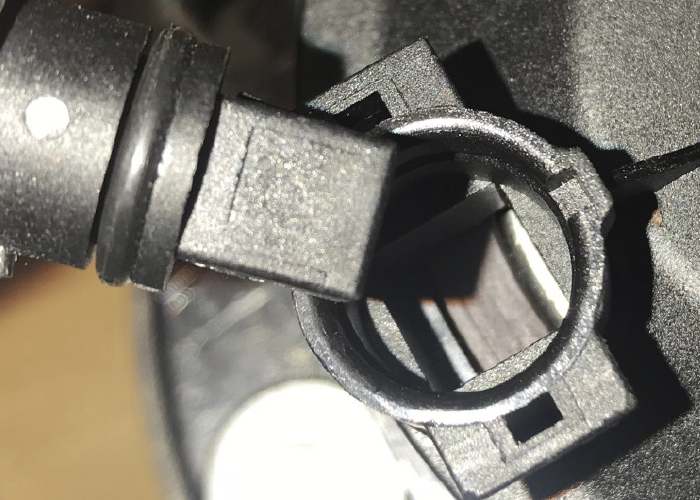

An active wheel speed sensor takes voltage from the ABS module (ranging from 8 to 12 volts) and changes the voltage signal by only 0.6 to 1.2 volts. The square wave’s peaks and valleys show the alternating polarity magnets in the encoder ring passing by the tip of the sensor. The faster the magnets pass by, the greater the frequency of the waveform, which is then translated into wheel speed by the ABS module. While this explanation might be oversimplified, it is enough knowledge to interpret the waveform.

Before you connect a scope, you need to better understand the circuit and bias voltage. The ABS module supplies voltage to the wheel speed sensor. The overall current levels of a wheel speed sensor circuit are low, but if the circuit is shorted to power or ground, there is potential to do damage to the circuitry in the module measuring small changes in voltage. There are no fuses in the wheel speed sensor circuit to protect the module. The module protects itself by sending out a low-voltage signal for a millisecond when it is first turned on and performs a self-check.

If the circuit is compromised by an open or short circuit, the increased or decreased resistance will cause the voltage to drop or exceed specifications. If the readings from the bias voltage tests are correct, the module provides voltage to the circuit for operation. If the readings are not in the predicted range, the module will not supply power, and will set a code and deactivate the ABS and stability control systems.

Bias voltage tests also work to detect opens in the circuit. This is why if a wheel speed sensor is disconnected it will cut power and set a code. When the untrained technician does not see power at the sensor, he may think the module is defective and replace the module.

To read the voltage with the system on, you will have to back-probe a connector or use a bypass harness to clear the code from the ABS module to test the circuit.