Q: What is a wheel hub bearing and why is it so important?

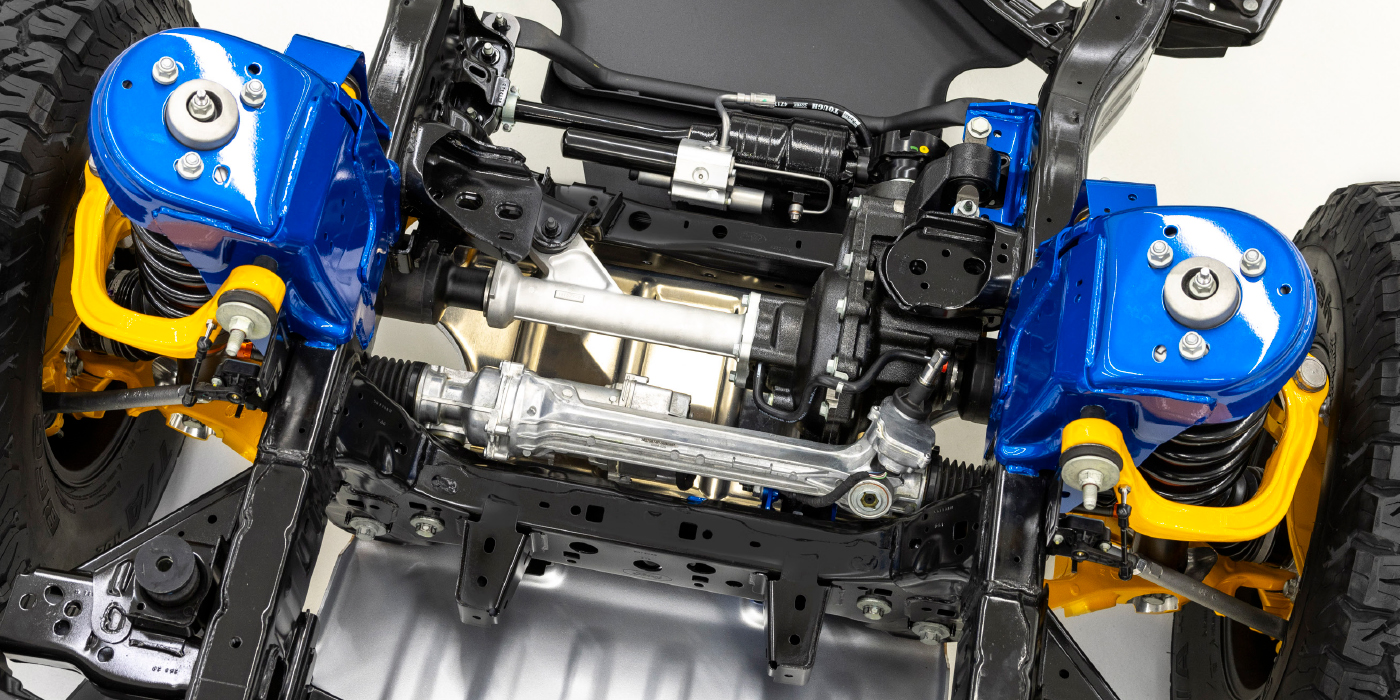

A: Though you may never even see it, a wheel hub bearing unit is an important part of a car’s wheel assembly, enabling wheels to turn freely and playing a crucial role in the safety and handling characteristics of a vehicle. Comprised of precision-manufactured bearings, seals and sensors in one pre-assembled unit, a wheel hub bearing unit is critical to performance — from the smoothness of the ride, to fuel efficiency, to the integrity of anti-lock braking systems (ABS).

Q: Why are “value grade” hubs a risky choice?

A: Many manufacturers sell replacement hub bearings that are very low priced and may seem like a great value at first. Unfortunately, with that low price, you get a low-quality hub bearing that is inferior to a premium, OE-quality hub bearing.

We call these hubs “value grade,” and experience has proven that these low-performing, value-grade hubs are no real value in the long run. In many cases:

• Value-grade hubs last less than half as long as premium hubs.

• Their seals can allow moisture and contaminants to enter and destroy the bearing prematurely — requiring a new hub in as little as 10,000 miles.

• They can produce annoying wheel vibration and noise.

• They can cause anti-lock braking systems to malfunction.

• They can result in the wheel coming off while the vehicle is in motion in extreme cases.

Q: How do hub bearings affect braking safety?

A: Hub bearings include the wheel speed sensor that controls the anti-lock braking system (ABS). This sensor sends a constant signal to the ABS control system, telling it how fast each wheel is turning. In an emergency situation, the ABS control system will determine if anti-lock braking is required.

If the ABS sensor doesn’t work properly or fails, the ABS system fails, so the quality of this sensor (how it is made and protected from damage) is critical to braking safety.

Q: Why are hub bearings critical to my traction control system?

A: A vehicle’s traction control system (TCS) uses a combination of electronic drivetrain controls in conjunction with the ABS system. Since it uses the same wheel speed sensors and components as the ABS system, it can be considered a subsystem and extension of that system. Together, ABS and TCS work to provide the driver with full control over the vehicle under potentially dangerous road conditions.

Provided by SKF.