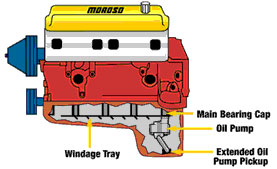

The use of a wet or dry sump oiling system is often determined by the level of competition and the racer’s budget. A wet sump system is based on the original equipment oiling system, and can be enhanced with certain components to improve oil control and increase power. A dry sump system is designed for the top levels of racing where maximum power and oil control are absolutely essential.

The use of a wet or dry sump oiling system is often determined by the level of competition and the racer’s budget. A wet sump system is based on the original equipment oiling system, and can be enhanced with certain components to improve oil control and increase power. A dry sump system is designed for the top levels of racing where maximum power and oil control are absolutely essential.

Oil Pan Capacities

Capacities listed for Moroso Wet Sump Oil Pans include the capacity of the pan only, measured at or below the normal fill mark on a stock dipstick. Additional oil must be added to compensate for filters, coolers, tanks, etc.

Unlike a wet sump system where oil is stored in the pan, a Dry Sump Oiling system stores oil in a separate tank — leaving the pan essentially "dry." An externally-mounted pump, generally with three or four stages, is used to "scavenge" or remove oil from the pan, deliver it to the storage tank, and send it back through the engine. In a typical setup, all but one of the stages is used to scavenge oil from the pan. A single pressure stage is normally used to return oil from the tank to the engine.

The primary advantage of a dry sump system is its ability to make more power. With very little oil in the pan, the rotating assembly is not burdened with the weight of excess oil (a phenomenon commonly referred to as "windage"). And because there is no internal pump, the windage tray or screen which serves to isolate sump oil from the rotating assembly, is allowed to run the full length of the pan. Keeping the rotating assembly free of windage allows it to spin freely and make more power. In addition, the extra crankcase vacuum created by the dry sump pump helps to improve ring seal for additional power gain.

Other advantages of a dry sump system include increased oil capacity, more consistent oil pressure, the ability to easily add remote coolers, and adjustable oil pressure. And because the pan doesn’t store oil, it can be relatively shallow in depth to allow lower engine placement for improved weight distribution and handling.

Moroso manufactures a full range of Dry Sump Oiling System components, all of which are engineered to be fully compatible with one another. This allows the engine builder to select the best combination of equipment and avoid the costly problems that often occur when "mixing and matching" components from various manufacturers.

Note: Oil pan rules vary from track to track. Check with your race track and/or sanctioning body before selecting your Moroso Oil Pan.

Tech Tip courtesy of Moroso.