I am a sucker for helping stranded motorists, and this pothole season is no exception. So far I have seen two lower ball joint failures, one u-joint pole vault and a separated tie rod. I think people are at their best when others are at their worst.

I am a sucker for helping stranded motorists, and this pothole season is no exception. So far I have seen two lower ball joint failures, one u-joint pole vault and a separated tie rod. I think people are at their best when others are at their worst.

I recently stopped to help a Subaru at the side of the road with a flat tire. The driver had removed a whole heap of junk from the trunk to get at the spare tire. The car was off the jack and the spare was on, but he was just standing there scratching his head.

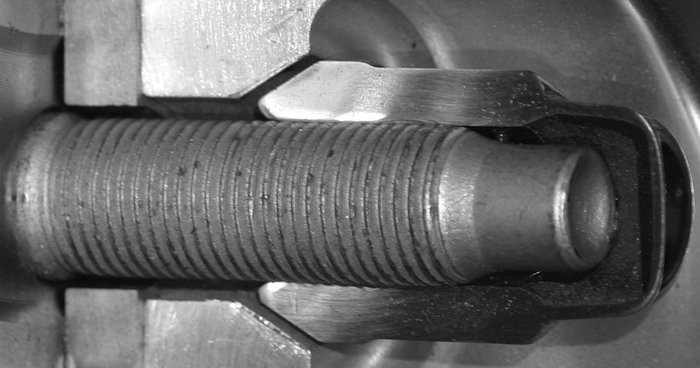

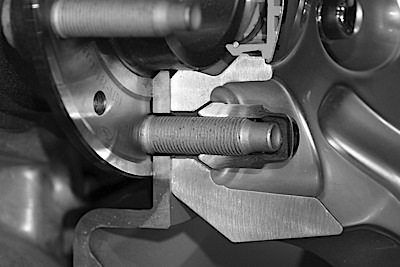

As I approached, I saw a very strange sight. He had managed to break two of the lug nuts and studs off the hub with the standard issue tire iron. One broke while removing the lug nut, and the other broke while tightening. He was not a large man, so I wondered if this was a case where this roadside emergency gave him super human powers.

Looking at the remaining studs, I saw a heavy coating of anti-seize. I asked if he put the anti-seize on the studs. He said that years ago he couldn’t get a wheel off his old car after it had a flat tire. He told me how he had to drive on the flat tire to a pay phone and trashed the rim.

Someone gave him some advice about anti-seize. So, when he bought his new car three years ago, he spent an afternoon applying anti-seize with a small paintbrush used for model cars to the studs.

This advice has been part of automotive folklore since anti-seize was invented. The first use of anti-seize was during WWII, where a stuck bolt could be the difference between life or death. These were large nuts on large vehicles like ships. The problem is this advice doesn’t apply for modern light vehicles.

If you apply any friction-modifying substance, like oil or anti-seize to threads, it is going to change the measured torque values. This is because the threads use friction between the two fasteners to clamp the two parts together. With less friction on the threads, torque values actually increase. So, when you tighten a wheel to 85 ft.-lbs, it may actually be torqued at 95 ft.-lbs (this includes torque wrenches and sticks) or more depending on how slick the lubricant was that was put on the studs.

The increase in force will mean that the studs will stretch under the increased torque. This stretching can lead to metal fatigue and changes in thread geometry. The Subaru driver had the car for three years. After a few tire rotations and maybe a few too many hits with an impact, the stud was ready to break.

The Bigger Problem

If you encounter one of these vehicles with anti-seize on the wheel studs, be very careful. Take time to explain to the driver why anti-seize is bad and how it can cause problems. Advise them that there is potential for failure during normal service. You should also put it on the repair order.

Is there a right way to use lubricants around the wheel? Yes, but it has to be a high-temperature lubricant used only in a very light coating. First, a high-temperature lubricant can be used where the hub goes through the center of the wheel. Many vehicles use the hub to center the wheel. These “hub-centric” designs can benefit from a very light coating.

On some conical lug nuts, you can put a light coating on the seating surfaces of the cone, while avoiding any contamination with the threads. No anti-seize on the threads.

We did manage to get the remaining three lug nuts on the wheel. I told him he should take it to a shop immediately to get the rest of the studs examined.