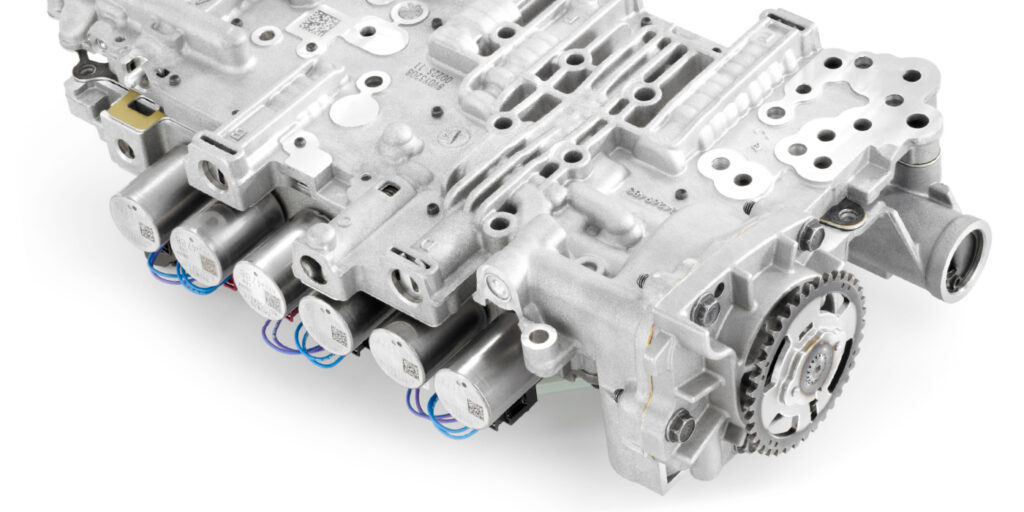

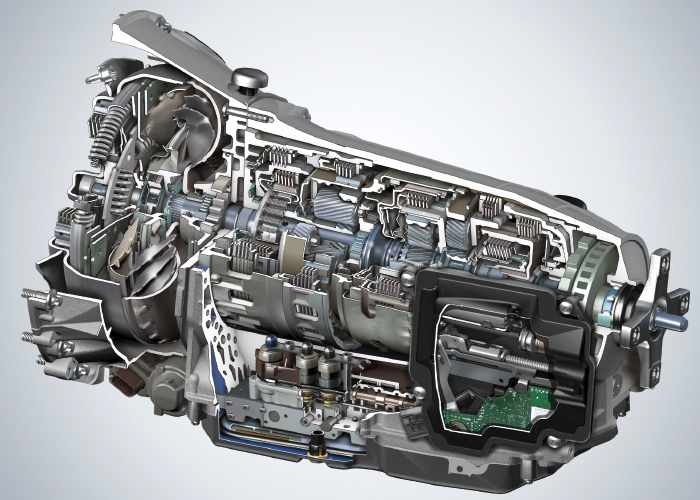

I would like to go over some basic (yet, very important) things that need to be done when replacing the valve body. I’ll also touch on some things that need to be done during an initial road test to help ensure everything goes as smoothly as possible.

Use lint-free shop rags: Always work with lint-free shop rags. When it comes to transmissions, cleanliness is imperative. Lint from rags is something you want to avoid at all costs, because lint loves to get in the sump filter and restrict it.

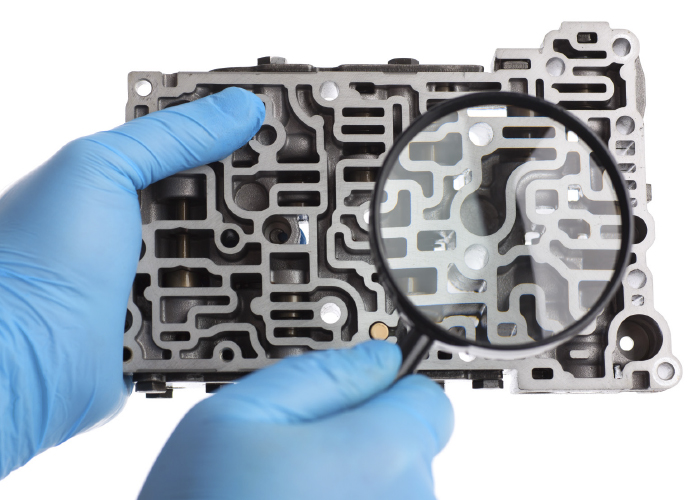

Air-check: While the valve body is out, be sure to air-check every clutch pack circuit that is accessible using low, regulated air pressure. It will help you discover any issues before you even install the valve body. But, above all, the importance of doing so is that should you have any shift concerns once finished – having notes on how each element air-checked can save you lots of diagnostic time. You are already in there, so the extra time it takes to do this quick check can save you hours later on.

Use a torque wrench: Always use a torque wrench in sequence on all the valve body bolts to ensure they are all torqued equally. I know many of us think that we have a torque wrench built into our arm but using a torque wrench goes a long way toward preventing castings from warping and valves from sticking by ensuring the torque is equal (and not too great) for all the bolts.

Make sure the manual valve is indexed properly: Double-check that the manual valve is indexed properly. I get calls from time to time for a no-move condition, simply because the manual valve was missed when installing the valve body. It is fairly easy to do on some valve bodies, especially when replacing the valve body with the transmission still in the vehicle.

Flushing the cooler lines and cooler: This is of the utmost importance. Over time various types of particles will lodge themselves in the nooks and crannies of the heat exchanger. New ATF cleans really well once the fluid is hot; the last thing you want is contamination that was present in the cooler circuit to break loose and end up in the valve body you just installed. Using a good-quality flusher that uses heated ATF is a must. If you don’t have access to one, replacing the radiator or bypassing the existing cooler is your next best option.

Check for DTCs: When replacing the valve body with the transmission in the vehicle (and before putting the pan back on), I strongly recommend that you take a minute to hook your scanner up to the vehicle, turn the key on and check for transmission codes. The vast majority of TCMs will detect a short or open circuit with just the Key On Engine Off. This is a quick and easy way to make sure everything is hooked up correctly, and that you don’t have any cut or pinched wires. All too often the solenoid looks like it is connected correctly, but in reality, it is not; either it just missed the terminal or it’s not all the way in. This causes the computer to trip a solenoid circuit code right away on startup.

Initial Test Drive: Check and confirm there are no DTCs in any vehicle modules. There must be no codes in any of the modules (in most cases) in order for the TCM to adapt to the new valve body and/or transmission you installed. If there is a code in another module, many times the computer will refuse to learn and adapt until the other issue is solved first. There is not always an easy way to find out for sure if a code in another module will prevent the computer from learning and adapting to the transmission. So, once again, it is a matter of paying attention to shift feel. If it remains the same no matter how long it is driven, more than likely the code in the other module is preventing it from adapting.

Reset the adaptive learning: If your scanner has a function to reset the adaptive learning, be sure to do it before going for a drive. It will reduce the time it takes to relearn the unit and keep the shift shocks, flares and bind-ups to a minimum from the get-go. Be aware that in some cases – some Toyotas and Lexuses, for example – the reset procedure with aftermarket scan tools can be a bit of a hit or miss. Many times, even if it says it is done successfully on the tool, it actually did nothing at all. If you are not sure if the function is doing what it should, first drive the vehicle, paying close attention to how it shifts. Then, reset the adaptive and drive it again to see if it made any difference at all in shift feel. It should have – sometimes better, sometimes worse – but it should make a difference. If you are dealing with one where it made no difference, then it might take a long time for it to adapt. And in some cases, it might never adapt until you have someone with a capable scan tool reset the adapts.

Bring the unit up to operating temperature: On most modern transmissions, the computer will not adapt until the unit has reached a certain temperature. How hot does it need to be? Good question. It is very rare for this information to be available. On some, it can be as low as 130° F, others as high as 160° F. To be on the safe side, I always recommend making sure the transmission temperature on your scanner indicates at least 170° F before wasting time driving it around, trying to get it to adapt. I cannot stress enough the importance of looking on the scanner at the temperature PID. On some vehicles, it is quite surprising how long it can take if you just drive it at one speed for the temperature to rise high enough.

Make sure there is enough gas in the tank: This next one is somewhat rare, but a major trap when you run into it. Make sure there is enough gas in the gas tank! That’s right, some vehicles out there will not relearn the transmission if the gas tank is below the one-fourth level. The reason for this, I am not sure. The only thing I can think of is that they want the monitor for fuel EVAP to run first, but that’s just a guess. What I am 100% sure of: I have run into this more than once and in more than one brand of vehicle, where a stubborn computer would not relearn at all, but started relearning when gasoline was added in the tank.

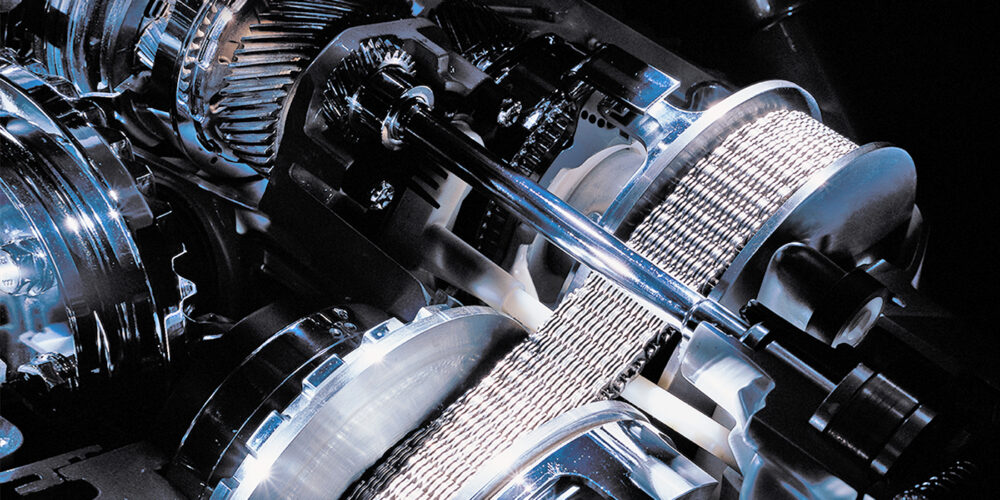

Relearn procedure: There are two sets of them on most transmissions: the garage shift feel and the upshift/downshifts.

- For the garage shift: With the transmission fluid showing to be above 170° F or above on your scanner, you want to move the shifter from reverse to neutral. Then go from neutral to drive, while stopping for 5 seconds in each range. Next, go back the other way, from drive to neutral and neutral to reverse. You should do this until the garage shift engagement becomes smooth. Some vehicles don’t have this adaptation. Some do it real quick, while others take a while. You have to pay attention to the way it engages to know if anything is happening and if it is done or not. Every other time or so that you put it in one range, it will feel different if it is adapting. Once it remains constant, the adaptation is complete.

- For the upshifts/downshifts: Many times, the computer will not adapt under somewhat irregular driving, so driving it too gently or too aggressively could prevent it from adapting. You want to drive it around in OD range, doing many upshifts and downshifts. Accelerate as you normally would under regular driving, all the way up every gear and coasting down at a normal rate of deceleration, all the way to a complete stop. Once again, the way to know if it is adapting is to pay attention to the shift feel. If it is still adapting every two or three times you perform a specific upshift, it will feel slightly different. Once it remains steady, you know it is done adapting.