Despite what you may believe about the properties of metal, bolts are actually elastic. It’s not quite Stretch Armstrong dramatic, but when you tighten a critical bolt to specs, you’re actually pulling it beyond its original length. Based on the quality of steel used in the fastener, the diameter of the fastener and how far you stretch it, the load or force applied to the joint (the two pieces being fastened together) changes.

The basic physics of all threaded fasteners are the same. Since metal is elastic, a clamping load is generated. The friction between the threads, bolt shoulders and even the washers creates additional clamping loads and friction to ensure the bolt does not turn and loosen. These loads are generated by the torque from a technician’s tools.

How much the fastener stretches is dependent on how much torque is applied. If too little torque is applied, the fastener will not generate enough clamping load and the assembly will come apart. If too much torque is applied, the fastener will snap or become elongated to the point where the geometry of the threads changes, and it won’t stay torqued.

Under the hood, the phrase “torque-to-yield” is well understood. With connecting rod bolt and cylinder head bolts and studs, the practice of following torque-to-yield (TTY) procedures is followed as standard operating procedure.

TTY fasteners are mounting fasteners which are torqued beyond the state of elasticity, and therefore, undergo “plastic” transformation that causes them to become permanently elongated.

Cylinder head bolts are under tremendous stress from the combustion process and must withstand incredible loads to keep the cylinder head sealed tightly against the head gasket and block. Head bolts may actually have to handle loads of more than five tons per bolt at wide-open throttle.

But what about under the car? These bolts and studs that stretch are becoming more common there as well. Many of today’s tie rods, ball joints and other suspension components actually use TTY fasteners.

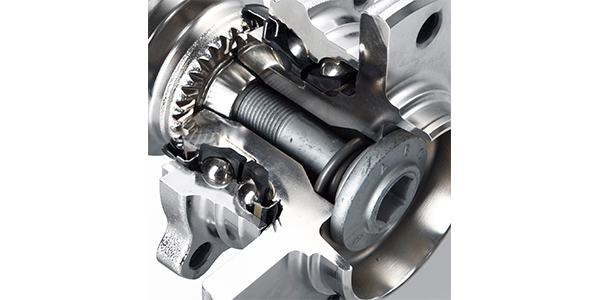

These TTY suspension fasteners are becoming more common as OEMs look to reduce unsprung mass in the suspension components. Some ball joints, and almost all tie-rod ends, use a tapered stud and hole with a nut on top to secure the stud to the knuckle. The 7-10º angled taper, along with a threaded stud and nut, lock the components together by tensioning the nut and stud.

TTY ball joint and tie-rod studs have two advantages. First, they can have a smaller footprint, weigh less and still apply the same clamping loads. Second, they offer far more consistent and controllable clamping loads.

Identification and Installation

Is a bolt a bolt? There are differences between standard and TTY bolts, both in metallurgy and heat treatment – you can sometimes tell one from the other by their appearance, but it’s always best to be sure by checking with your supplier. Always make sure to check the service information to get the right torque for a suspension component regardless of the type of fastener. If you see an initial torque spec along with an angle in degrees, it is in reference to a TTY fastener.

TTY ball joints and tie rods are usually installed dry. Lubricants reduce friction when a bolt is tightened, which increases the torque load on the bolt or stud, potentially overloading and stretching a TTY bolt too far, causing it to break.

The increased torque can also cause the female part of the taper to crack as too much clamping force is applied. The first word in TTY is torque, and you must do the job right using the right tools.

Some components like aluminum knuckles, upper control arms and ball joints can be damaged if not tightened using the correct procedure. Knuckles and upper control arms are aluminum and can be damaged if a torque wrench and torque angle gauge are not used.

Many ball joints may have an initial torque spec as low as 15-30 ft./lbs., and torque angles are between 140º and 225º. Make sure you check the service information to see if a TTY ball joint or tie-rod end is reusable after it has been removed. Some manufacturers recommend that a joint be replaced, while others do not indicate if it should.

No matter if you go too tight or too loose, if you fail to use correct tools and procedures, you could be buying the customer new suspension parts. It’s always safest, of course, to follow the OEM specification for any part that, if it breaks, can cause injury or death.

The torque specifications for components are much more exact now – just look at any service bulletin. Fastener requirements mean many nuts and bolts are more vehicle specific, so using the right part is critical – and hoping to simply replace one you may have inadvertently damaged may not be as easy as you think. Remember, no matter how close you think you are to perfect, if your torque wrench isn’t accurately calibrated, you’ll never know how far you are off in either direction while installing the parts.

A shop setting can be a very dangerous environment for precision equipment like your torque wrench. Wrenches are often returned to their case without being wound down to the lowest setting. Failure to wind down the wrench to the lowest scale before storing it leaves the mainspring compressed, which can weaken the spring and cause false readings. In addition, going to zero or past zero can affect the calibration of the wrench.

Another common problem occurs when the torque wrench is dropped on the ground. While one fall from a workbench may not damage the accuracy, repeated blows can cause a calibration problem. And never use your torque wrench as a breaker bar.

If you have “community property” torque tools at your shop that are used to tighten lug nuts, oil drain plugs or TPMS sensors, calibration on a more frequent basis is recommended.

It is critical that the wrench be calibrated by a service provider that is accredited by a testing laboratory, and that you are provided with documentation on the accuracy of the torque wrench. This can help to cover your liability if a wheel comes off a vehicle or a drain plug falls out.

Do things wrong and you may suffer the minor inconvenience of a PR headache – or something more serious. Following proper procedures will help you avoid these potential problems.