A valve stem is a critical safety component that keeps air in the tires. It is exposed to extreme forces, corrosive chemicals and the heat generated by the brakes. Not replacing the TPMS sensor service kit when the tire is removed from the rim can create a sensor issue.

A valve stem is a critical safety component that keeps air in the tires. It is exposed to extreme forces, corrosive chemicals and the heat generated by the brakes. Not replacing the TPMS sensor service kit when the tire is removed from the rim can create a sensor issue.

Every time a tire is removed from the rim, the TPMS kit must be serviced. This goes for sensor service kits that are six days old to ones that are six years old. Some drivers may complain, but it is a lot better than having them come back with the TPMS light on.

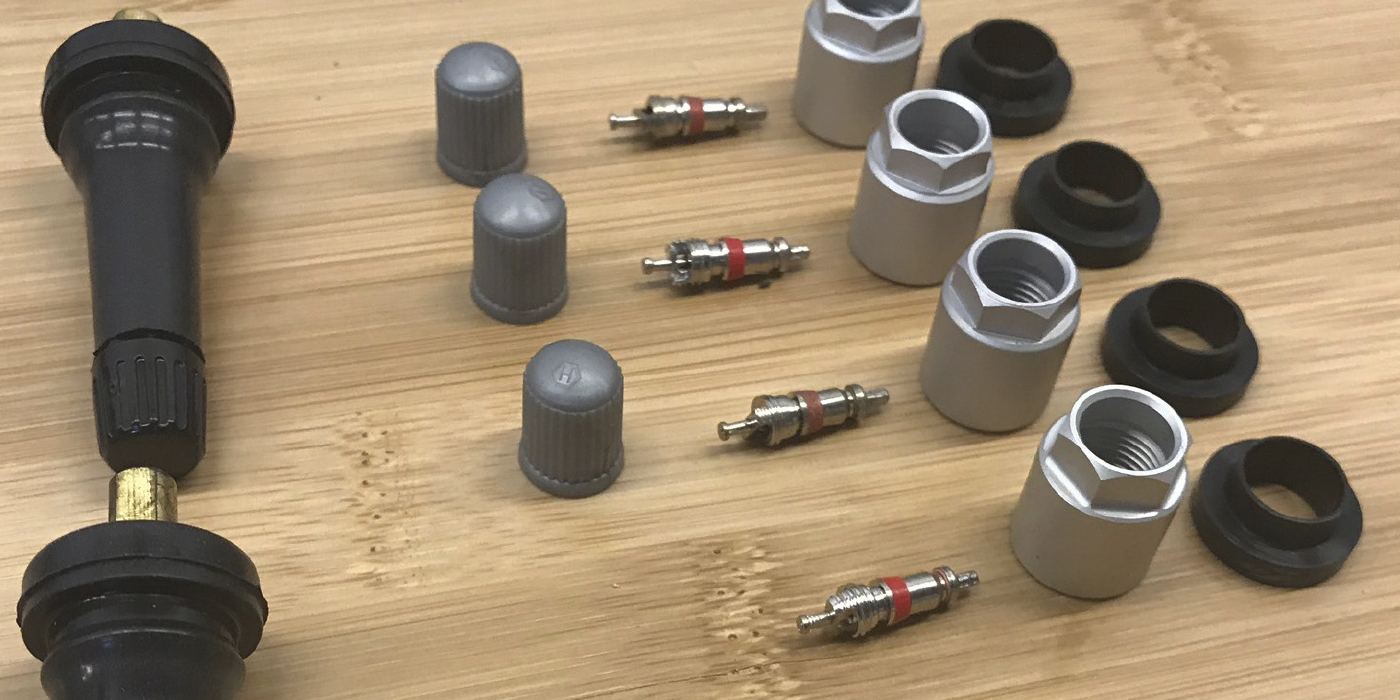

The typical kit for a clamp-on sensor includes a nut, valve core, grommets and valve cap. Each component has a specific function and lifespan that is not only determined by time, but by what happens when it is installed.

TPMS nuts are constructed with anodized aluminum to eliminate the contact of two dissimilar metals that would create galvanic corrosion and material deterioration. The nut has a bonded lubricant to help provide the proper torque required for seating a new grommet, in addition to other engineering advantages.

If a nut is reused, the anodized surface may be scratched away and corrosion may occur between the sensor, wheel and stem. It may even make the nut impossible to torque to the correct specifications or remove due to corrosion on the threads.

If a nut is reused, the anodized surface may be scratched away and corrosion may occur between the sensor, wheel and stem. It may even make the nut impossible to torque to the correct specifications or remove due to corrosion on the threads.

On the stem and nut, two grommets seal the sensor and nut to the wheel. Grommets conform to the mating surface of the rim and specific clamping pressure. The instant the nut is torqued, it starts to take on the shape of the surfaces it is sealing against. This memory cannot be erased. If the seal is reused, it could cause a slow leak.

The leak cannot be eliminated by tightening the nut even more. Extra force may damage the nut and stem or fracture the sensor body.

The valve core is nickel plated and prevents galvanic corrosion and ensures integrity of the primary seal. To prevent galvanic corrosion, never use a brass valve core with an aluminum TPMS sensor. Instead, always use a nickel-plated valve core with an aluminum TPMS sensor. The kit should have the right one. If the wrong valve core is used, accelerated galvanic corrosion could result in the core becoming “frozen,” stuck in the stem and unable to be removed. Also, TPMS valve cores have special Teflon coatings that help seat and seal the stem.

Snap-in sensors can look like regular rubber valve stems. But, the molded rubber on the snap-in valve stem does not reach the threads. These valves have a longer cap than a non-TPMS valve stem.

Snap-in sensors can look like regular rubber valve stems. But, the molded rubber on the snap-in valve stem does not reach the threads. These valves have a longer cap than a non-TPMS valve stem.

Behind the stem is a mounting point for a self-tapping screw that holds the sensor to the stem. There are two installation methods depending on the type of snap-in valve stem you are installing. Always check the instructions or the manufacturer’s recommendation.

The first method is installing the valve stem in the rim and then attaching the sensor. The second method is to attach the sensor to the valve stem and then insert it into the wheel. Why? On some stems, the sensor could come in contact with the wheel as the stem is pulled with the sensor attached.

When attaching a new valve to the sensor body, always use a preset torque screwdriver with the correct torx head or hex nut. Most tool suppliers package two preset torque drivers in a set. Due to different manufacturers, the torque settings may differ. The screw is self-tapping and can only be used once, the same also applies to the stem.

When tightening the screw, be mindful of stress on the sensor and its alignment. Start the screw for the first couple of threads and make sure the sensor and stem are aligned. When performing the final tightening sequence, stop when the tool clicks, indicating the proper torque has been reached.