The center support bearing is a relatively small component in a mid-sized vehicle, yet a properly-functioning bearing is crucial both to consistent overall performance and to avoiding damage to other vehicle components. Possible indications of a failing center bearing should be investigated promptly, and a worn or damaged center bearing must be replaced immediately with a quality option.

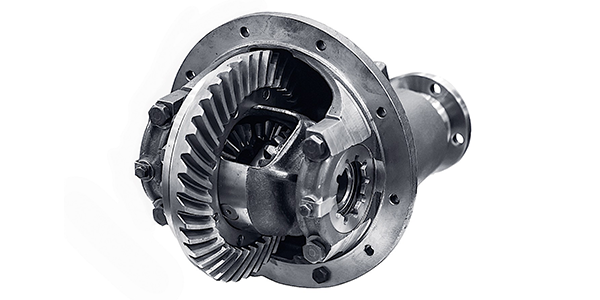

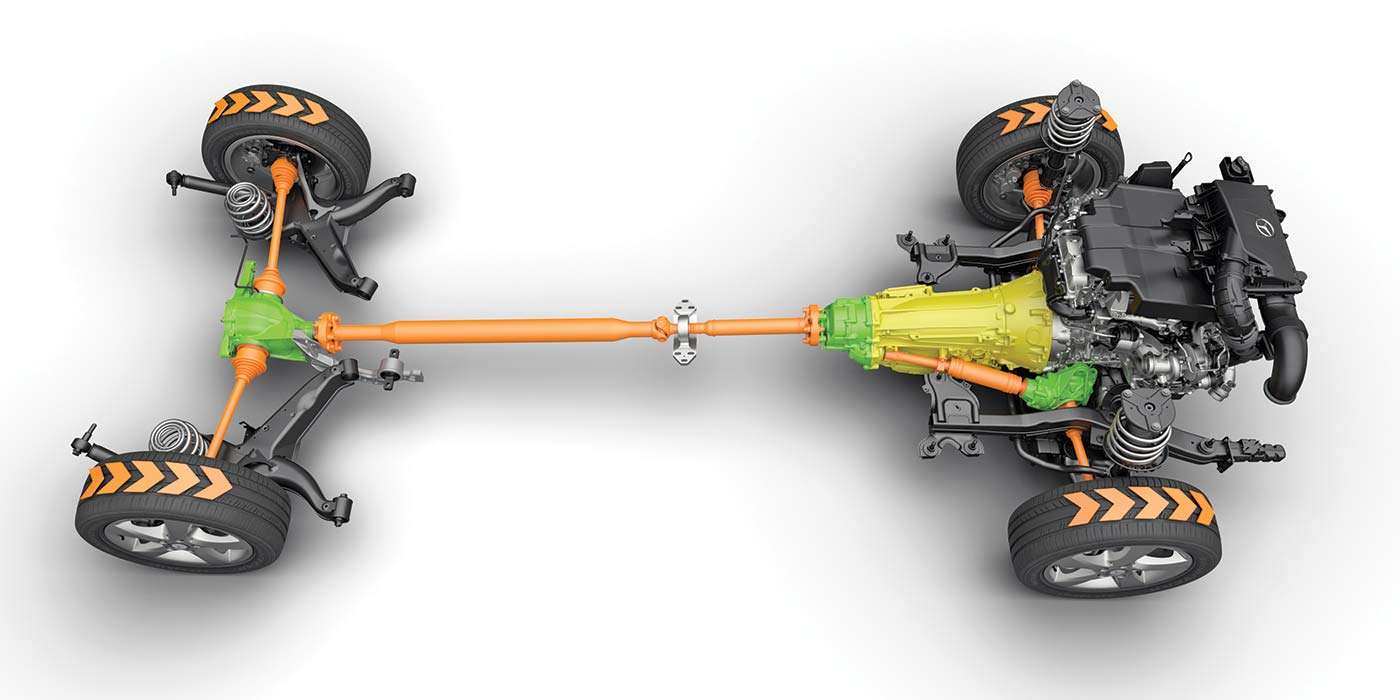

A center bearing provides essential support for a vehicle’s driveshaft, which connects the transmission to the rear differential so that the rear wheels may turn. A longer driveshaft can put strain on driveshaft components; the center support bearing provides a measure of flexibly to the driveshaft, alleviating some of that strain and allowing the driveshaft to spin easily. The center bearing permits the shaft to turn as it should even if it isn’t perfectly straight. In addition, it absorbs vibrations associated with driving on rough roads or down a trail.

When a center bearing becomes worn due to constant use or is damaged, there are three common symptoms that may alert an operator to the issue. The first is a shuddering or shaking that occurs when accelerating the vehicle after a complete stop. In this case, the failing bearing is no longer providing proper support to the driveshaft, so the shaft begins to flex improperly. The shuddering puts strain on the drivetrain components, making the vehicle less responsive when turning. The second indicator involves a sense of diminished performance or of resistance when driving—sometimes described as a binding feeling. The third sign of a possible problem with a center bearing is unusual noises. These noises occur when accelerating or decelerating, and can include grinding, squealing, squeaking, and howling.

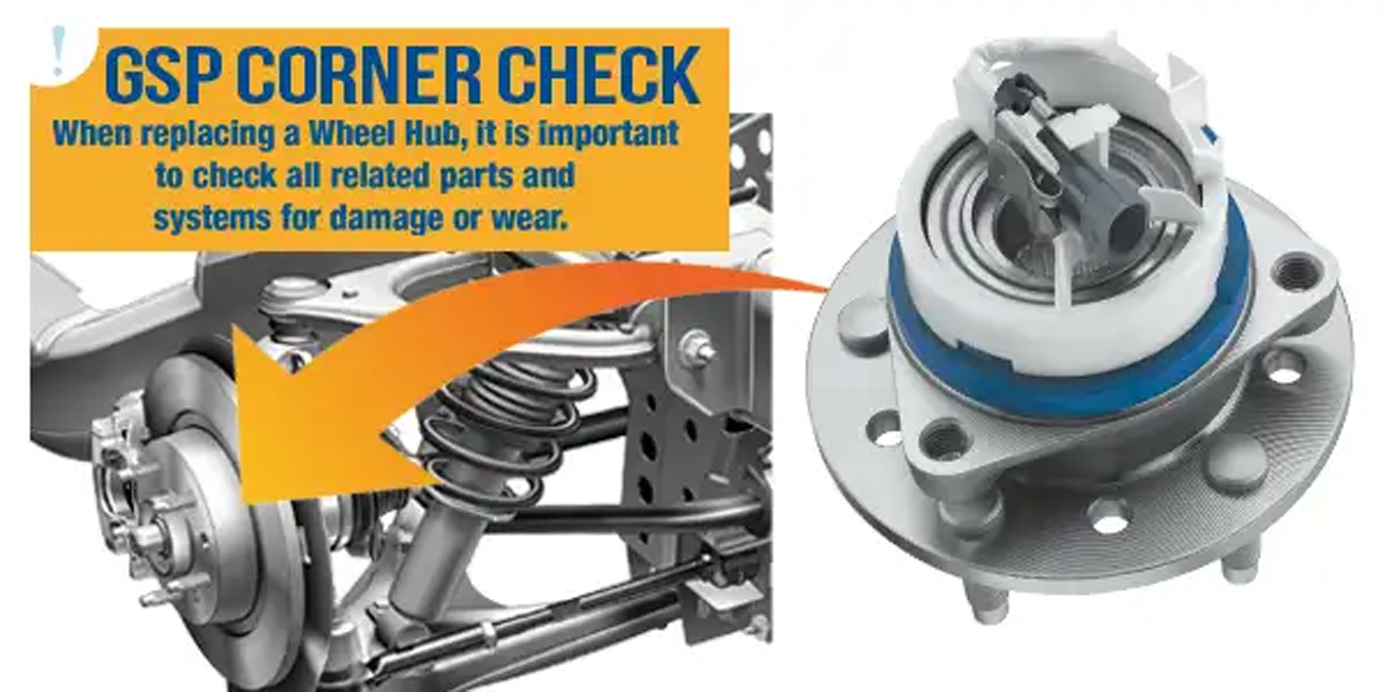

As soon as any of these problems is detected, the vehicle should be brought in for inspection. If the issue is ignored, other components such as the differential, driveshaft, or transmission may suffer serious damage. For example, if the center support bearing completely fails, the driveshaft may flex to the extent that it comes in contact with the underside of the vehicle, causing damage and turning a simple part replacement into extensive downtime and repairs.

Replacement is necessary if a worn center bearing is determined to be the cause of any of the symptoms above. When selecting a new, aftermarket center bearing, resist the urge to purchase an inferior part to save a few dollars up-front. Center bearings are precision parts that demand sophisticated manufacturing procedures and choice materials. A subpar part will only result in premature failure and further repairs. And while low-priced bearings may seem very similar to higher-quality bearings at first glance, the difference becomes clear later, when dealing with a comeback or a frustrated customer.

Selecting a center bearing designed for performance and durability will ensure years of dependable service. Key components to shop for include brackets made of high-quality steel and the correct rubber hardness to ensure a smooth, quiet ride. Of course, a design that adheres to original equipment specifications will guarantee a proper fit.

For a line of aftermarket center bearings that features all of these benefits, check out the Spicer Select™ light vehicle center support bearings manufactured by the driveline experts at Dana. Engineered with premium aftermarket-grade bearings, they are proven to last for the life of a vehicle. In order to serve a wider range of customers in search of quality parts, this line of bearings was recently expanded. The increased coverage includes applications for high-volume vehicles in operation (VIO) like Chevrolet® Silverado trucks and fleet-managed last mile delivery Dodge® and Mercedes® Sprinter vans.

The center support bearing in a light vehicle will likely wear out over the years or become damaged. When this happens, being aware of the signs that this part may soon fail can help prevent further damage to related parts. Replacing the center bearing will avoid extended downtime, and choosing a quality option ensures years of reliable service to come.