By Eric Seifert

Automotive Technical Editor

Chris enjoys going camping in his 2004 Jeep Wrangler. During a weekend in the mountains, the Wrangler began to make a “chirping” noise. Chris said that using the low range 4WD caused the noise to become louder.

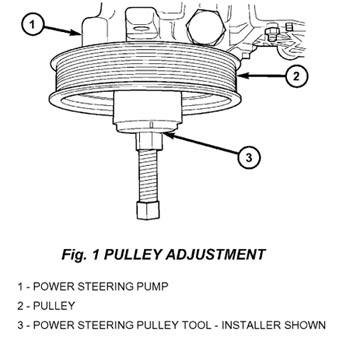

The customer may experience a chirp-like sound coming from the accessory drive belt. The sound may become more pronounced at higher engine speeds. Investigation may reveal accelerated accessory drive belt wear even though the belt is properly installed on all pulleys. The accessory drive belt chirp-like sound may be caused by the misalignment of the power steering pump pulley to the shaft of the power steering pump. The pulley may have been installed too far (over-installed) onto the pump shaft. The front surface of the power steering pump pulley hub should be flush with the end of the power steering pump shaft.

Diagnosis:

Determine if the front end of the power steering pulley hub is flush with the leading edge of the power steering pump shaft. If the symptom/condition is present, and the front end/edge of the power steering pulley hub is not flush with the leading edge of the power steering pump shaft, then perform the Repair Procedure.

A special tool, MATCO MST93 Pulley Remover/Installer (or equivalent), along with a new drive belt will be required to complete the repair. For the 2.4L engine, use Chrysler drive belt P/N 05281351AC with A/C or 53013352AD without A/C (or equivalent). For the 4.0L engine, use Chrysler drive belt P/N 04854033AB with A/C or 53013209AC without A/C (or equivalent).

Applicable Vehicles: 2004 Wrangler (TJ)

Repair Procedure: Review safety procedures in ALLDATA Repair before beginning.

Repair Procedure: Review safety procedures in ALLDATA Repair before beginning.

1. Disconnect the negative battery cable from the battery.

2. Install Matco MST93 puller tool (or equivalent), on the steering pump pulley. Align the power steering pump pulley so that the front surface/face of the pulley hub is flush with the end of the power steering pump shaft. Maximum tolerance is 0 +/- 0.127 mm (0.005 in.) (Figure 1).

3. Install a new accessory drive belt. Make sure the belt is properly seated to all pulleys.

4. Connect the negative battery cable to the battery.

NOTE: The procedure to replace the Power Steering Pump Pulley in ALLDATA offers additional insight for the technician regarding alignment of the pump pulley.

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience.

Technical service bulletin courtesy of ALLDATA.

For additional information, visit www.alldata.com.