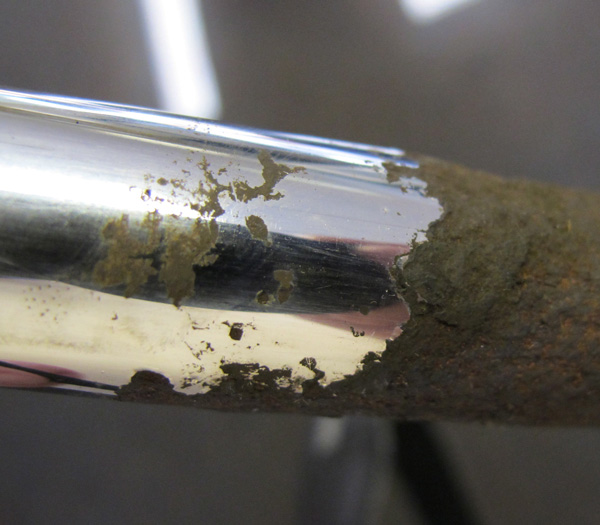

3_01_2009/86804PistonSeal_00000041859.jpg” border=”0″ ” align=”right” alt=”one area of wear is the seal between the piston and bore. the seal must prevent fluid from flowing between the two surfaces without creating excessive amounts of friction. if the seal allows to much fluid to pass, it will influence how the valves in the piston and base perform. if the fluid becomes contaminated, it can cause wear to the bore and piston. according to some shock and strut suppliers, wear on these surfaces does not happen until the unit has become significantly degraded. “/>

BendPak Founder Don Henthorn Passes Away

Grew company from small machine shop to global leader in car lifts and garage equipment.

Don Henthorn, owner and founder of BendPak Inc., peacefully passed away at home Thursday, March 28, at the age of 85. Under his leadership, BendPak has grown from a small machine shop to one of the world’s leading manufacturers of car lifts and automotive service equipment.

Management and operations of the privately owned company are unchanged.

High-End Ride Control Rehab

Electronically adjustable shocks and struts use conventional mono-tube and twin-tube oil-filled dampeners.

Toe Angles and Tie Rods

It is critical to remember that toe is not always zero or straight ahead.

ADAS Module Programming

Reflashing and reprogramming is a necessary service for repairing vehicles.

Live Axle Wheel Bearing Service

Replacing rear wheel bearings on a live axle rear suspension requires a few extra steps when compared to a unitized bearing.

Other Posts

ASE Practice Tests Available Online

You can get a good idea of what to expect by adding the official ASE practice tests to their study plans.

AACF Celebrates 65 Years Serving the Aftermarket

AACF will be announcing more details about this commemorative fundraiser April 1st.

Auto Care Association Launches REPAIR Act Video

The goal is to emphasize the need for federal REPAIR Act legislation, according to the Auto Care Association.

Valvoline Celebrates Female Service Center Employees

Valvoline is launching a social media campaign led by its female experts who are sharing automotive preventive maintenance tips to promote accessible vehicle care for all.