Use the following procedure to replace the piston cooling valve on model-year 2000 S70, V70 and C70 Volvos.

SERVICE PROCEDURE:

1. Remove the timing belt. See VADIS: Function Group 2, Repair/Removal, replacement and installation, Section 21 Engine, Replacing the timing belt/idler pulley/belt tensioner.

2. Remove the timing belt tensioner.

3. Remove the ider pulley.

4. Remove the screw securing the inner timing cover to the cylinder head.

5. Raise the car. Continue with VADIS method: Replacing the timing belt/idler pulley/belt tensioner.

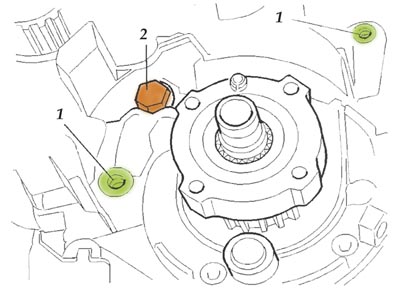

6. Remove the vibration damper. 7. Remove the two screws (see Fig. 1, 1) securing the inner timing cover to the cylinder block.

7. Remove the two screws (see Fig. 1, 1) securing the inner timing cover to the cylinder block.

8. Lower the belt guard at the oil pump housing.

9. Press the inner timing cover off the flange around the coolant pump. Start at the lower edge of the pump.

10. Hold the cover out of the way. Remove the piston cooling valve (See Fig. 1, 2) and the seal washer.

11. Install a new piston cooling valve (P/N 9497918) and the seal washer (P/N 11998).

12. Install the inner timing cover. First press the cover into place over the flange at the top of the coolant pump. Then press the remaining section of the cover into place over the flange around the pump. Check that the cover is positioned correctly.

13. Install the two screws securing the inner timing cover to the cylinder block.

14. Install the lower belt guard.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.