By Eric Seifert

ALLDATA Automotive Technical Editor

Steve enjoys mountain biking, and his 2001 Subaru Legacy has no problem getting him to the mountains and back. Yet it doesn’t like to commute. Steve called me after work one day to inquire about a surging problem the Legacy has had for a while. He said that the car would surge in low-speed traffic, especially after reaching operating temperature. We scheduled an appointment and I did some research. I discovered that the surging problem is common to some newer model Subarus.

If you encounter a driveability concern such as idle surges or whistling, it may be caused by carbon buildup on the Idle Speed Control (ISC) valve. In these cases, it is not necessary to replace the ISC valve. Cleaning the ISC valve could correct the condition. To clean an ISC valve, perform the repair procedure.

Applicable Vehicles

1999 Legacy 2.2L CAL

2000-’01 Legacy 2.5L MT

All Legacy 3.0L MT

2004 Baja 2.5L Turbo

1999 Impreza 2.2L CAL

2000-’01 Impreza 2.2L

2002-’04 Impreza 2.0/2.5L Turbo

REPAIR PROCEDURE

Normally Aspirated Vehicles:

1. Warm up the engine.

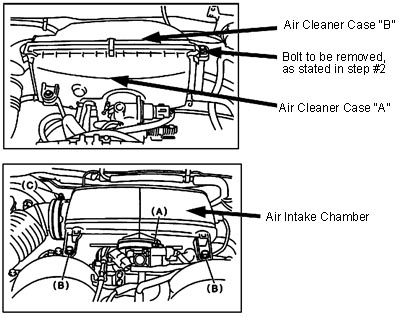

2. On 2.2L/2.5L engines only, remove the bolt that attaches air cleaner case B to the bracket. See Figure 1. Undo the three clips that hold together air cleaner case B to air cleaner case A. Remove air cleaner case B and the air cleaner element and set aside. (On all 3.0L H6, remove the entire air intake chamber).

3. Start the car and maintain engine speed between 1,000 and 1,500 rpm.

4. Spray engine cleaner (GM P/N 12345089 GM Top Engine Cleaner or equivalent) toward the upper air-stream of the throttle chamber for approximately 10 seconds.

5. Stop the engine and let it sit for three minutes.

6. Restart the engine and maintain 1,000 to 1,500 rpm.

7. Spray engine cleaner on the upper air-stream of the throttle chamber for approximately 10 seconds.

8. Turn off the engine.

9. Reinstall the air cleaner element and air cleaner case B.

10. Operate the car between 1,000 and 2,000 rpm until no white smoke appears through the tailpipe.

11. Turn off the ignition switch and clear the memory.

For Turbo Vehicles:

1. Warm up the engine.

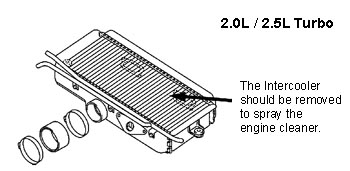

2. Remove the intercooler (see Figure 2) and set aside. 3. Disconnect the mass airflow (MAF) sensor connector.

3. Disconnect the mass airflow (MAF) sensor connector.

4. Cycle the key “on/off” once (to enter “failsafe” mode).

5. Start the car and maintain engine speed between 1,000-1,500 rpm.

6. Spray engine cleaner (GM P/N 12345089 Top Engine Cleaner or equivalent) on the upper air-stream of the throttle chamber for approximately 10 seconds.

7. Stop the engine and let it sit for three minutes.

8. Restart the engine and maintain 1,000 to 1,500 rpm.

9. Spray engine cleaner on the upper air-stream of the throttle chamber for approximately 10 seconds.

10. Turn off the engine.

11. Reinstall the intercooler and reconnect the MAF sensor connector.

12. Operate the car between 1,000-2,000 rpm until no white smoke appears through the tailpipe.

13. Turn off the ignition switch and clear the memory.

Written by ALLDATA Technical Editor Eric Seifert, an ASE certified Master Technician and Engine Machinist, with 20 years of independent shop and parts store experience.

For additional information, visit www.alldata.com.