The AERA (Engine Rebuilders Association) Technical Committee offers the following information regarding cylinder head installation for 2002-’05 Subaru 2.0L DOHC EJ20DT engines. This information is somewhat unique and should be referenced any time a cylinder head is re-installed.

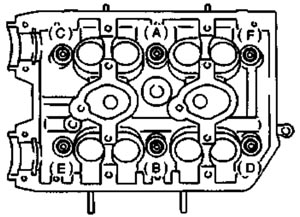

This engine requires pre-stressing the cylinder head gasket and then a relaxing procedure when installing the cylinder head. Failure to follow the following procedure (Figure 1, 2002-’05 Subaru 2.0L DOHC cylinder head installation procedure) may result in premature head gasket failure.

Apply a coat of clean engine oil to washers and bolt threads.

Apply a coat of clean engine oil to washers and bolt threads.

1. Torque all bolts to 22 ft.-lbs. (29 Nm) in alphabetical sequence.

2. Torque all bolts to 51 ft.-lbs. (69 Nm) in alphabetical sequence.

3. Loosen all bolts in reverse alphabetical sequence 180°.

4. Loosen all bolts, yet one more time in reverse alphabetical sequence 180°.

5. Torque all bolts 29 ft.-lbs. (39 Nm).

6. Tighten all bolts 80-90° of rotation in alphabetical sequence.

7. Tighten all bolts 40-45° of rotation in alphabetical sequence.

Caution: Do not tighten the bolts more than 40-45°.

8. Further tighten only bolts A and B 40-45° of rotation in alphabetical sequence.

Courtesy of AERA.