If you are having trouble removing a drum-in-hat rotor, don’t just take a hammer to it. You may have to adjust the parking brake and back it off the rotor in order to remove the rear rotor.

This problem is common in vehicles where drivers don’t often use the parking brake. When the parking brake isn’t used, rust and corrosion build up inside the drum. This causes the drum-in-hat rotor to stick to the parking brake. Therefore, to remove the rotor, you have to back the parking brake off the drum lining.

Repair Procedure:

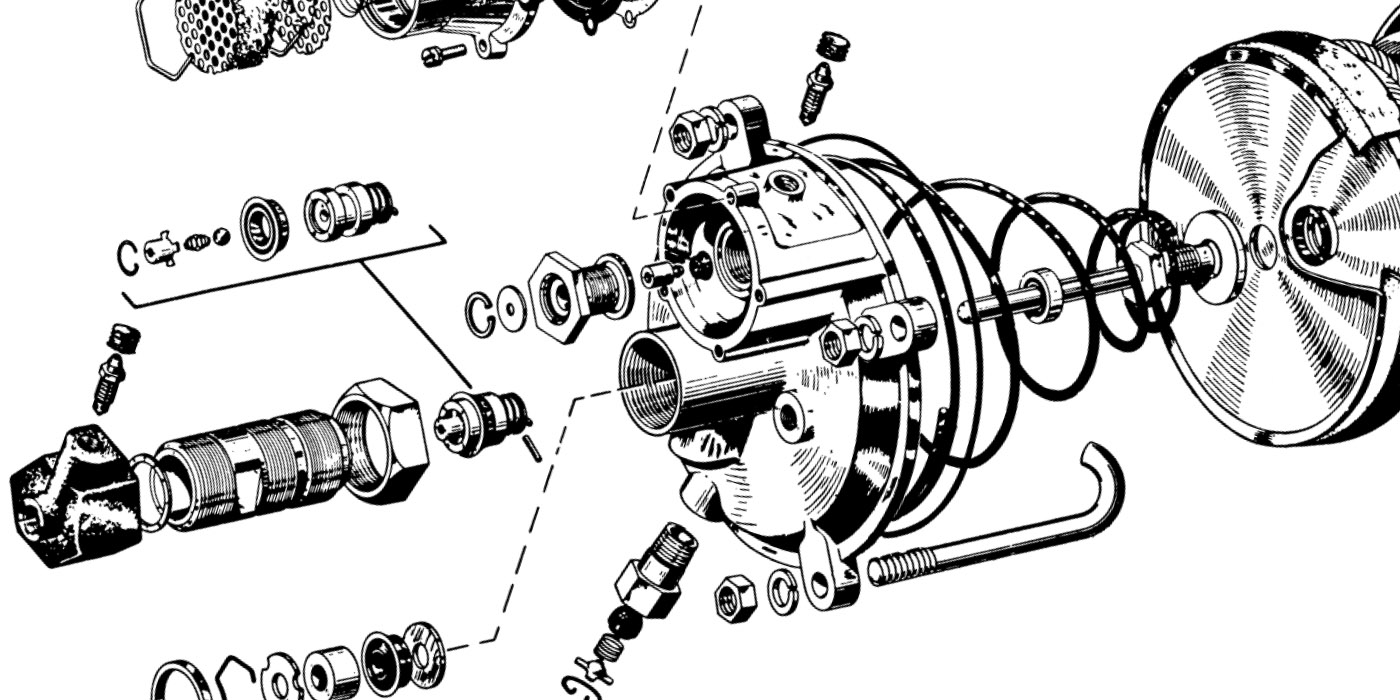

To adjust the parking brake, you need to locate the access hole on the rotor (see Figure 1). Some rotors have the access hole on the hat of the rotor. Others are found in the back of the rotor (see Figure 2).

Take the rubber plug off the rotor. Then, use a brake spoon or a flathead screwdriver to turn the adjuster wheel. Usually, a few clicks of the wheel will do the trick. If you don’t know which direction to turn the wheel, start rotating the adjuster while spinning the rotor. If you are turning the adjuster the wrong way, you will feel the drag.

Once you back the parking brake off, you may still need to tap on the rotor with a hammer to get the rotor off.

But, now you won’t risk damaging the parking brake assembly. With the rotor off, it is important that you inspect the parking brake assembly. Make sure to check the lining of the parking brake shoes, along with the hardware.

Courtesy of Raybestos/Brake Parts Inc