Application:

Power steering equipped-vehicles with a remote mounted pump reservoir.

Problem:

Replacement power steering pump produces no pressure, pump is noisy, or fluid over-flows after shutdown.

Cause:

Possible restricted flow out of reservoir or an air-bound system due to a restriction in the system.

Solution:

Solution:

Service the remote reservoir and fill the pump and reservoir as follows:

1. Drain all fluid from the remote reservoir and remove it for inspection.

2. Flush and check reservoir for damage.

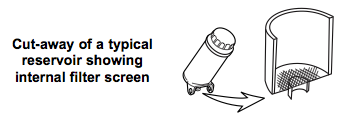

3. Many reservoirs have a filter or strainer in the bottom that can become blocked with debris or contamination. Test the flow through that filter by pouring some fluid into the reservoir. Look for fluid to freely flow from the reservoir outlet. Flush or replace reservoir as needed to obtain proper flow.

4. Before reinstalling the reservoir, inspect the feed hose between the reservoir and the pump for damage or restriction. This hose often passes near the exhaust manifold and can become soft enough to collapse under the draw of the pump. Replace the hose if there is any indication of damage or doubt of its condition.

5. Install the reservoir, connecting the feed hose to the remote reservoir, but do not connect it to the pump yet. Place the open end of the hose in a catch can, fill reservoir with fluid and allow fluid to flow from the hose until no air is present.

6. Now connect the hose to the pump and complete the installation and bleeding as per the vehicle service manual and any supplied instructions.

7. Be sure to inspect and replace other hoses as needed in the power steering system.

For more information see ProTech PT 20-0005 and PT 20-0016. The installation of an external filter to protect the system is highly recommended (PT 20-0021), and it is very important to use OE approved or equivalent fluid (PT 20-0027).

Note:

Please refer to your vehicle’s service manual for specific diagnostic instructions. This ProTech bulletin is supplied as technical information only and is not an authorization for repair.

Tech Tip courtesy of CARDONE Industries, Inc.