Karl enjoys watching classic movies, especially ones involving exploration and adventure. Many of his favorites feature a Land Rover. He can see himself commanding a safari expedition, perched atop his Rover, on the lookout for big game. Unfortunately, the reality of carting kids to baseball and soccer practice leaves little time for African safaris.

One adventure he enjoys in his 2003 Range Rover is weekend camping with his family. Upon returning from his most recent camping excursion, Karl called about a problem with the car. He said that the Range Rover had developed a vibration in the steering wheel, but only when he stepped on the brake pedal. I did some research and found a solution to his problem.

Customers may report that a vibration or “judder” is felt in the steering wheel during braking. The front brake discs may have worn unevenly, resulting in thickness variations on the disc. The remedy is to install two new front brake discs (Land Rover P/N SDB000201) in combination with new specification front brake pads (Land Rover P/N SFC500050).

APPLICABLE VEHICLES

New Range Rover (LM) up to 4A 159171.

REPAIR PROCEDURE

(Review Brake Pad and Rotor replacement along with safety procedures.)

1. Remove the front brake pads.

2. Remove and replace each front rotor as follows:

– Remove the two bolts securing the left-hand brake caliper to the hub.

CAUTION: The caliper MUST NEVER hang on the brake hose during the repair.

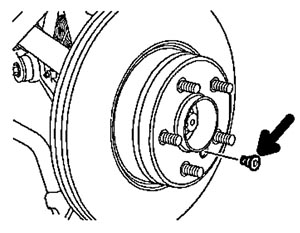

– Release the caliper from the hub and tie aside avoiding strain on the brake hose. – Remove the Allen screw securing the brake disc to the drive flange and remove the disc. (Figure 1).

– Remove the Allen screw securing the brake disc to the drive flange and remove the disc. (Figure 1).

– Ensure the mating surfaces of the new disc and of the drive flange are clean.

– Install a new disc (SDB000201) to the flange. Install Allen screw and tighten to 16 Nm (12 lbf.ft).

– Position the caliper to the hub, install bolts and tighten to 110 Nm (81 lbf.ft).

3. Perform step 2 on the alternate side brake disc.

4. Install the new front brake pads (SFC500050).

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience.

For information on products offered by ALLDATA, visit www.alldata.com.