In this technical bulletin, SKF provides updated technical information for preventing ABS sensor failure in pigtail style hub assemblies.

In this technical bulletin, SKF provides updated technical information for preventing ABS sensor failure in pigtail style hub assemblies.

ABS system failures that happen shortly after hub unit installation can cause concern and customer dissatisfaction. Several items should be checked during the replacement process to prevent additional unnecessary repairs:

• After removal of old hub unit, make sure the steering knuckle is clean from rust. Excessive rust can lead to improper seating of hub assembly.

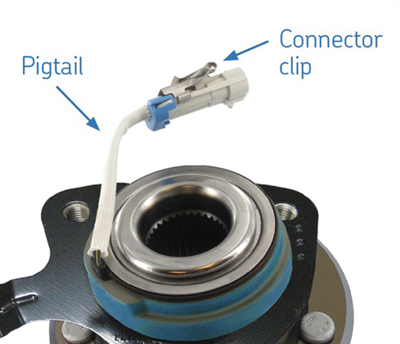

• During installation, make sure the pigtail connector is routed correctly and not pinched in the knuckle.

• The connector clip must be completely seated on the backing plate. Failure to seat the clip will cause excessive movement in the pigtail wiring and internal damage will occur. The connector must also be properly secured to the harness connector.

• Make sure the weather pack has not fallen out of the harness. Replace if missing. Without the weather pack, water intrusion will occur damaging both the ABS sensor on the hub and the harness side wiring and connector. Visually inspect the connectors for signs of corrosion.

• Also note that during testing of the ABS system during a sensor failure, the ABS harness should be checked for breaks and/or resistance failures. A resistance check should be done from the ABS module to the end of the harness connector.

• During the final installation process, make sure the axle nut is torqued correctly.

Note: Incorrect torque can damage the sensor cap and allow for water intrusion.

Incorrect torque will also cause premature bearing failure.

Figure 1 shows a typical pigtail-style hub assembly with backing plate. This style is most common to GM vehicles. The arrows in the figure are pointing to the ABS pigtail and pigtail connector clip. The clip may be metal or plastic.

For more information about SKF and its premium quality products and services, contact your local SKF representative, or visit www.vsm.skf.com.