By Rich Diegle

Senior Automotive Editor

A simple electrical problem can be a major inconvenience for owners of some Mitsubishi Eclipse and Galant models. Some vehicles may intermittently experience loss of power to items such as: radio, dome light, sun visor vanity light and remote keyless entry.

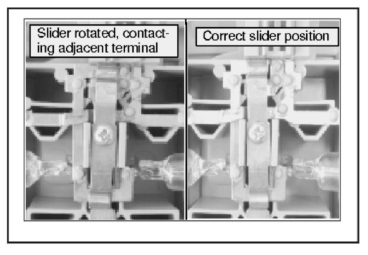

The dome light switch slider may become loose, allowing the slider to rotate and contact the adjacent terminal. This causes a short circuit, which blows the IOD fuse (indicated below). The fuse typically will blow when the dome light switch is in the OFF position and the Remote Keyless Entry transmitter LOCK or UNLOCK button is pushed.

Model Years IOD Fuse

1999 – 2001 #4

2002 #18

2003 – 2005 #22

Affected Vehicles

2000 – 2005 Eclipse models without factory-installed sunroof

1999 – 2003 Galant

Required Part

Super glue

Repair Procedure

(Review safety procedures in ALLDATA Repair before beginning.)

1. Remove the dome light assembly.

1. Remove the dome light assembly.

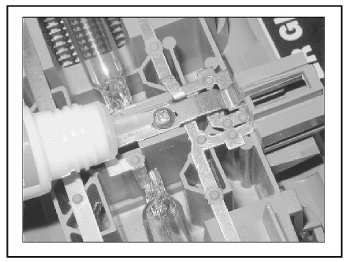

2. Inspect the position of the dome light switch slider bar with the switch in the OFF position (see photo). The screw securing the switch slider may come loose, allowing the slider to rotate and contact the adjacent terminal.

3. If the slider bar is loose and in the incorrect position, move it to the correct position and tighten the screw securely.

4. Apply a drop of super glue on the screw and slider to keep the screw from loosening and the slider from moving.

5. Reinstall the dome light assembly into the vehicle.

5. Reinstall the dome light assembly into the vehicle.

6. Replace the dedicated IOD fuse and confirm operation of the affected functions.

Written by ALLDATA Senior Automotive Editor, Rich Diegle. Rich is an Advanced Engine Performance Certified, ASE Master Technician with an AA Degree in automotive technology and 23 years of dealership and independent shop experience.

For additional information, visit www.alldata.com.