By Rich Diegle

Incorrect oil levels are being found in many 2002-2003 Ford, Lincoln and Mercury vehicles. In most cases, the level is being misinterpreted because the oil level on the dipstick is not touching the top hash mark at the upper limit (or MAX mark), or it is partway down the crosshatch area.

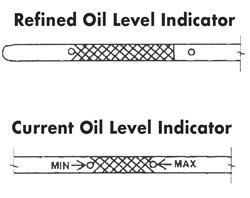

Ford is in the process of standardizing the marking across all vehicle lines. The markings shown in Figure 1 were scheduled to be upgraded to a refined marking, but both markings were still being used in many 2004 and 2005 models. Oil levels will continue to be recorded in the crosshatched area of the blade, between the upper and lower limit holes. Vehicles with engine oil levels falling within this area are acceptable and do not require topping off.

Ford is in the process of standardizing the marking across all vehicle lines. The markings shown in Figure 1 were scheduled to be upgraded to a refined marking, but both markings were still being used in many 2004 and 2005 models. Oil levels will continue to be recorded in the crosshatched area of the blade, between the upper and lower limit holes. Vehicles with engine oil levels falling within this area are acceptable and do not require topping off.

SERVICE PROCEDURE

Ensure the vehicle is sitting on level ground. Set the parking brake and make sure the transmission selector lever is in the Park position or in First gear on manual transmissions. The engine must be off.

The best time for determining oil level is after the oil has had sufficient drain-back time to the sump. If the engine has been running, allow it to sit for a few minutes turned off. An oil drain-back period is required before taking an initial reading.

If the level falls below the lower hole, fill with one quart of oil. If one quart is insufficient to raise the level above the lower mark, add oil until it records within the crosshatch area. Use caution during this procedure as some time is needed for oil to drain down through the drain-back passages in the cylinder head to the oil pan. Adding oil a quart at a time repeatedly without sufficient drain-back may overfill the sump.

If the oil level falls between the upper and lower holes, do not add more oil. Adding an extra quart could cause overfilling and may result in aeration (foaming) causing eventual damage to vital bearing surfaces and moving parts inside. Overfilling will require some oil to be drained until the indicator shows the level between the upper and lower holes of the blade. An extra quart of oil should never be considered as additional lubrication protection for the engine.

For additional information on ALLDATA, visit www.alldata.com.

Rich Diegle is technical editor at ALLDATA. Diegle is an Advanced Engine Performance Certified ASE Master Technician with an AA degree in automotive technology and 23 years of dealership and independent shop experience.