by Eric Seifert

ALLDATA Automotive Technical Editor

Squeaks from the rear of 2002 to 2005 Mitsubishi Outlanders or Lancers, most noticeable when traveling over speed bumps, may be caused by a corroded outer lower control arm bushing.

Water intrusion through the control arm bushing seal may allow corrosion, resulting in a squeak during control arm movement. The factory-recommended repair is to replace the parts with updated versions that are designed to prevent water intrusion.

After test driving the vehicle to confirm the customer’s complaint, confirm that the source of the noise is from the upper or lower control arm (or both).

If the noise is NOT coming from a rear control arm, diagnose and repair/replace the appropriate component(s), as necessary. Do not continue with this procedure.

NOTE: Control arm components on U.S. vehicles are different than those on Canadian vehicles.

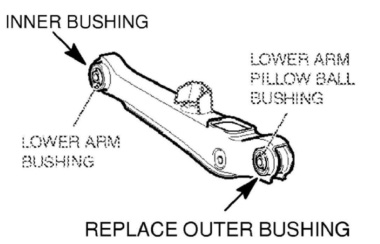

Lower Rear Control Arm Bushing:

• 4113A062 (Lancer and Outlander U.S. only)

Lower Rear Control Arm Assembly:

• MR491963 (Lancer Canada only)

• 4113A035 (03-04 Outlander Canada only)

• 4113A033 (05 Outlander Canada only)

Upper Rear Control Arm Assembly:

• MN100086 (05 Outlander, 04-05 Lancer 2.4L MIVEC)

• MN100107 (03-04 Outlander)

Applicable Vehicles:

• 2002-05 Lancer (except ES models)

• 2004 Lancer Sportback built before: 4/18/05 (U.S.); 9/2/04 (Canada)

• 2003-05 Outlander built before: 4/18/05 (U.S.); 9/2/04 (Canada)

Service Procedure:

(Review safety procedures contained in ALLDATA Repair before beginning.)  1. On the side of the vehicle where the noise occurs, determine whether the noise occurs at the upper or the lower control arm or both. Use the new parts listed in the introduction of this article.

1. On the side of the vehicle where the noise occurs, determine whether the noise occurs at the upper or the lower control arm or both. Use the new parts listed in the introduction of this article.

U.S. Vehicles

• If the noise occurs at the lower control arm, replace the lower control arm outer (pillow ball) bushing.

• If the noise occurs at the upper control arm, replace the upper control arm assembly.

Lower Arm Bushing (Outer Pillow Ball Bushing) Replacement Procedure

• Drive out the old bushings and pressfit the new bushing.

NOTE: After pressfitting, the space between the edges of the bushing outer sleeve and the lower arm should be 3 mm (0.120 inch).

NOTE: After pressfitting, the space between the edges of the bushing outer sleeve and the lower arm should be 3 mm (0.120 inch).

Canadian Vehicles

• If the noise occurs at the lower control arm, replace the lower control arm assembly.

• If the noise occurs at the upper control arm, replace the upper control arm assembly.

2. Test drive the vehicle to confirm the squeaking noise is eliminated.

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience.

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.