Vehicles affected: Ford: 2000-’07 Taurus and Windstar; 2004-’07 Freestar; Mercury: 2000-’05 Sable; 2004-’07 Monterey

Some of the above vehicles, equipped with a 4F50N, AX4N or AX4S transaxle, may exhibit an erratic fluid level reading on the transaxle dipstick and possible leaks around the filler tube and grommet.

The condition may be due to a restricted transaxle vent.

Repair the transaxle vent restriction by replacing the transaxle vent with a 90° vent stem, small hose clamp, two tie raps and 24” (61 cm) of 5/16” (8 mm) vacuum hose.

The 5/16” (8 mm) vacuum hose will be routed from the 90° vent on the transaxle back to the cowl area, next to the brake master cylinder and tie rapped in place with the end of the hose facing down.

Refer to the following Service Procedures.

Note: On Windstar, Freestar and Monterey vehicles, seal the cowl panel grille (cowl to vent panel) area; see TSB 06-14-10.

Note: On Windstar, Freestar and Monterey vehicles, seal the cowl panel grille (cowl to vent panel) area; see TSB 06-14-10.

Note: Leaks may be misdiagnosed as coming from the pan gasket. Always follow workshop manual, Section 307-01 to locate the source of a leak, and leak check with black light and dye.

Service Procedure

1. Disconnect the mass air flow (MAF) sensor electrical connector.

2. Disconnect the crankcase vent tube(s) from the air cleaner outlet pipe.

3. Loosen the clamp and disconnect the air cleaner outlet pipe from the throttle body.

4. Release the air cleaner housing clamp(s).

5. Separate the air cleaner cover from the air cleaner tray.

6. Windstar, Freestar and Monterey only: Remove the cowl panel grille by following the procedure in TSB 06-14-10.

6. Windstar, Freestar and Monterey only: Remove the cowl panel grille by following the procedure in TSB 06-14-10.

7. Disconnect the shift cable if located over the top of the vent.

8. Remove the vent; pull straight up on the vent with locking pliers, or carefully pry the vent from the transaxle case.

9. Install the replacement 90° vent stem.

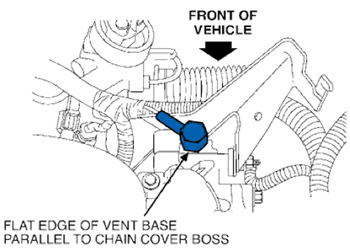

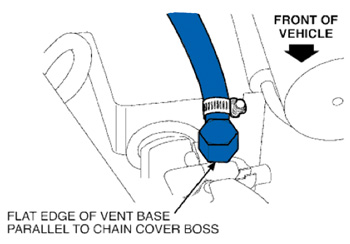

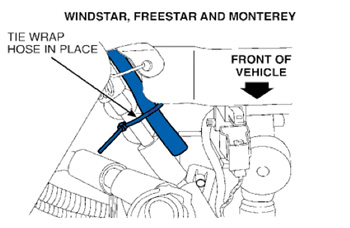

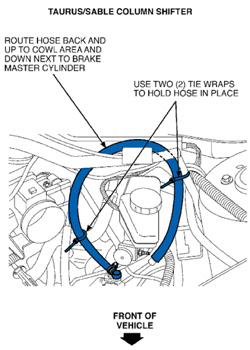

– Windstar, Freestar, Monterey, Taurus and Sable with column shifter: Must face to the right rear of the vehicle with the flat edge of vent base parallel to the chain cover boss (Figure 1).

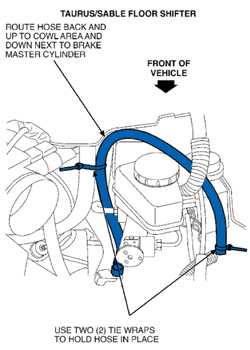

– Taurus and Sable with floor shifter: Must face to the rear of the vehicle with the flat edge of vent base parallel to the chain cover boss (Figure 2).

10. Install one end of a 24” (61 cm) long piece of 5/16” (8 mm) vacuum hose to the 90° vent stem and secure with a small hose clamp.

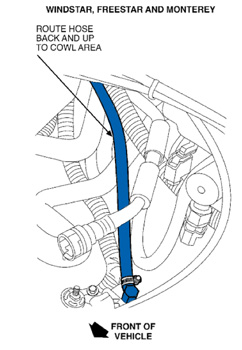

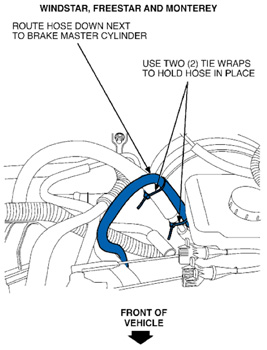

11. Route the vacuum hose back and up to the cowl area and down next to the brake master cylinder.

Carefully tie rap the hose in place next to the brake master cylinder (do not tie rap to brake lines), be sure the end of the hose is facing down and not directly above anything hot.

– Windstar Freestar and Monterey (Figure 3, 4 and 5)

– Taurus and Sable with column shifter (Figure 6)

– Taurus with floor shifter (Figure 7)

12. Connect the shift cable, if removed.

13. Install the air cleaner cover and outlet pipe.

13. Install the air cleaner cover and outlet pipe.

Note: Use the alignment notches to correctly align the air cleaner cover to the air cleaner tray.

14. Install the air cleaner housing clamp(s).

15. Connect the air cleaner outlet pipe to the throttle body and tighten to 35 lb.-in. (4 Nm).

16. Connect the crankcase vent tube to the air cleaner outlet pipe.

17. Connect the MAF sensor electrical connector.

18. Windstar, Freestar and Monterey only: Follow TSB 06-14-10 to seal and install the cowl panel grille.

Courtesy of Mitchell 1.