Edited by Ed Dorowski, ALLDATA editor, and Jeff Webster, ALLDATA technical writer

Some Toyota 4Runner owners may complain of a condition where the blower motor speed does not match the HVAC display indication. A new/modified blower motor controller is available to address the condition. Follow the repair procedure described in this Tech Tip to resolve the problem.

Applicable Vehicles: 2003-’05 4Runner vehicles produced before these Production Change Effective VINs:

JTEZT14R*50021434 JTEZT14R*58006730

JTEZT17R*50021445 JTEZT17R*58006732

JTEBT14R*50049429 JTEBT14R*58023054

JTEBT17R*50049446 JTEBT17R*58023046

JTEZU14R*50056705 JTEZU14R*58033837

JTEZU17R*50056704 JTEZU17R*58033901

JTEBU14*50068373 JTEBU14R*58044478

JTEBU17R*50068397 JTEBU17R*58044471

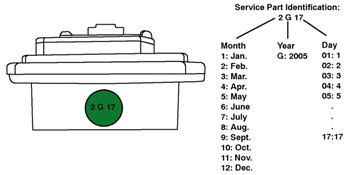

Parts Identification

Countermeasure service parts are identified by the four-digit date code printed on the side of the blower motor controller cooling fins. Date code is 2 G 17 or later (see Figure 1).

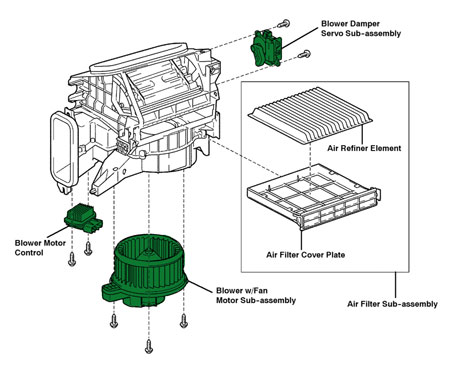

Components

See Figure 2.

Repair Procedure

1. Remove the negative (-) battery terminal.

Note: Failure to complete step 1 may result in internal damage to the transfer case shifting mechanism.

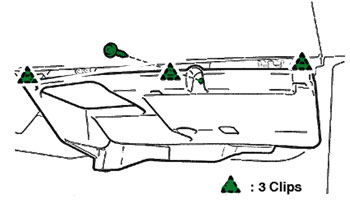

2. Remove the instrument panel under cover sub-assembly No. 2 (see Figure 3).

a. Remove the screw and disengage the three clips.

b. Disconnect the wire harness from the 4WD computer.

c. Remove the instrument panel under cover

sub-assembly No. 2.

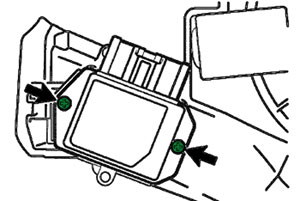

3. Remove the blower motor controller.

a. Disconnect the wire harness connector.

b. Remove the two retaining screws (see Figure 4).

c. Remove the blower motor controller from the HVAC module.

4. Install the new blower motor controller (P/N 87165).

a. Insert the blower motor controller into the HVAC module.

b. Install the two retaining screws.

c. Connect the wire harness.

5. Reconnect the 4WD computer.

6. Install the instrument panel under cover

sub-assembly No. 2.

7. Reconnect the negative (-) battery terminal.

8. Confirm proper blower motor operation and speed control.

9. When the negative (-) battery cable is reconnected, check and reset electrical components, such as the clock, radio, etc., and re-initialize all applicable systems/functions.