In the import car aftermarket, warranties are one of the biggest concerns for installers and parts manufacturers.

“Job comebacks” greatly reduce productivity and profitability for installers, not to mention the loss of repeat business and negative word of mouth.

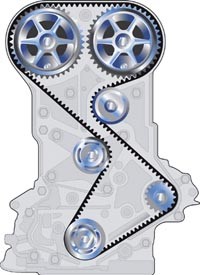

When servicing the import timing system, many technicians replace only the worn belt. They overlook the tensioner, tensioner pulleys and idlers because failure modes such as misalignment, loss of lubricant and weak spring force are often hard to detect.

When servicing the import timing system, many technicians replace only the worn belt. They overlook the tensioner, tensioner pulleys and idlers because failure modes such as misalignment, loss of lubricant and weak spring force are often hard to detect. It is highly probable that the source of belt damage or premature belt failure is the result of wear on the timing system’s other rotating components.

If the tensioners, pulleys and idler are not replaced along with the belt, Gates Corporation engineers say the drive system could fail within a few thousand miles. To reduce belt warranty problems, comebacks and labor claims, Gates recommends that all timing system components be replaced at the same time.

They say many belt failures can be reduced by following the advice in OE and shop manuals.

Typically, the instructions recommend: "Check idler pulley or drive belt tensioner for smooth operation and noise. Inspect timing belt tensioner for signs of oil or grease leakage. Replace defective components."

In an effort to reduce comebacks to installers due to an unexpected timing system failure, Gates offers a line of nearly 120 timing component kits. With the available matching cam/crank oil seals, you have all of the parts needed for a timing belt system replacement.

Gates offers broad coverage of timing component kits with belts. All kit components are built to OE fit and quality, and 75 percent of Gates kits are applicable to import vehicles – from Acuras to Yugos. So, the next time you replace a broken timing belt, or service a related part, such as a water pump, ask your jobber for a Gates timing component kit.

Gates offers broad coverage of timing component kits with belts. All kit components are built to OE fit and quality, and 75 percent of Gates kits are applicable to import vehicles – from Acuras to Yugos. So, the next time you replace a broken timing belt, or service a related part, such as a water pump, ask your jobber for a Gates timing component kit.