By Dave Hobbs,

By Dave Hobbs,

Delphi Product & Service Solutions service trainer

In addition to his work with Delphi, Dave Hobbs serves as an instructor for Indiana’s Ivy Tech Community College. He is also a frequent speaker at national training seminars, is a qualified hybrid instructor and writes for various industry magazines.

Two decades of training engineers and service technicians around the world has provided Hobbs the unique ability to bridge the theoretical with the practical.

Today, Hobbs talks with us about turbochargers and superchargers — what they are, how they run and what technicians can expect when servicing or installing these engine performance

components.

Q: In the simplest terms, what are turbochargers and superchargers?

A: Turbochargers and superchargers are engine performance devices that increase the volumetric efficiency (VE) of any engine. Increased VE delivers more air to the engine; more air means more power.

A: Turbochargers and superchargers are engine performance devices that increase the volumetric efficiency (VE) of any engine. Increased VE delivers more air to the engine; more air means more power.

For example, a larger engine, such as a V8, delivers more power than a 4-cylinder engine. Turbochargers and superchargers allow that 4-cylinder engine to perform like a larger engine.

An engine without a turbocharger is called normally aspirated (it “breathes” normally) versus a turbocharged engine having forced air delivered to it for more power.

Q: What is the difference between the two?

A: Turbochargers and superchargers both incorporate a turbine type fan to force air into the engine. The difference is in the make-up and set up of the two. The supercharger fan, or turbine, is mechanically turned by a belt. The belt drives the fan to force air into the engine. The belt is connected to the crankshaft.

This requires horsepower — you use energy to make energy. Essentially, it’s another fan belt on the front of the engine that forces air into the device for increased engine performance.

The turbocharger is an exhaust gas-driven turbine fan. It uses exhaust pressure to spin the turbine and compresses the air entering the engine, pulling it through the system by the crankshaft, forcing fresh air into the engine.

Like hydropower, it’s “free” energy. You are using the waste of the engine to create more power, more performance. It’s a more efficient way to force air into the system.

Q: When were turbochargers and superchargers invented? Where are they found?

Q: When were turbochargers and superchargers invented? Where are they found?

A: It may surprise you, but both turbochargers and superchargers have been around since the early 1900s, used on diesel and gas-powered engines, light-duty and heavy-duty vehicles. And traditionally, turbochargers and superchargers are associated with performance vehicles.

With the push for 34.1 mpg in CAFE 2016, developing engines that deliver performance while maintaining fuel efficiencies and controlled emissions is critical.

In addition to hybrids and electric vehicles, smaller engines are being developed to meet these emissions standards.

Turbochargers and superchargers can help with the expected performance and still deliver the required efficiencies.

For example, the new Chevrolet Cruze Eco delivers 42 mpg on the highway with its 1.4L, 4-cylinder engine. How? It has an integrated turbocharger unit to deliver better boost power, decrease turbo lag, all while maintaining fuel economy and emissions performance.

Q: What is boost and turbo lag?

A: Boost pressure basically is the “go” the turbocharger provides the engine. However, it’s important to note that boost pressure needs to be maintained. Too much, and damage to the engine could occur over a period of time.

In order to reap the benefits of turbocharging, boost pressure in turn makes the engine components hotter. As more compressed air is forced through the system, the hotter the engine’s combustion temperatures will be.

It’s important to find the “sweet spot” of boost pressure — where can I get the most performance without potentially harming the engine?

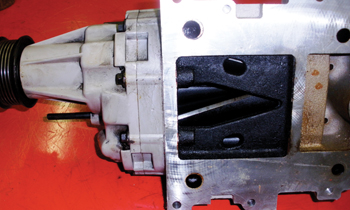

For background, turbos and superchargers both operate at a higher rpm than the engine itself. The turbocharger turbine is designed like a pinwheel to catch the air, draw it through and deliver it to the engine. This is called vane technology.

The supercharger has more of roller swirling style of fan. One such design is called a Roots-style blower. Both generate heat under operation. If the boost pressure is too high you could overheat the engine, causing engine failures such as a blown head gasket. Vehicle manufacturers have boost pressure limitations for that specific reason — to protect the engine.

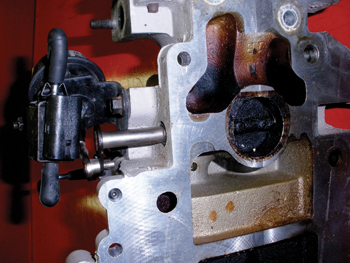

One way to temper boost pressure is to cool the heat generated. This can be done through oil to lubricate the supercharger or turbocharger. Synthetic engine oil is superior because it withstands increased engine temperatures better. However, the oil needs to be maintained and, as much as we would like, it’s a known fact drivers don’t change their oil as often as they should.

Plus, this provides one more area that oil is required to ensure the engine is running optimally. This increases the stress on oil usage. Oil temperature, quality and maintenance are key issues when it comes to turbochargers and superchargers. And specific to turbochargers, which use exhaust gas to spin the turbine and oil to cool it, this can create problems for the oil. Oil does not like to be hot and dirty.

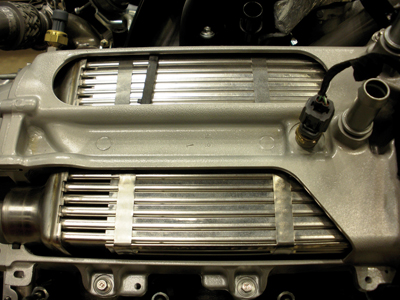

Also, with both chargers, when you compress air to deliver forced air to the engine, that compressed air is warmer; it doesn’t carry as much oxygen. Remember, keeping the engine cool is critical. You can compensate for that with inter-coolers, which are heat exchangers incorporated into the intake airflow to help take turbocharged compressed air and cool it to make more oxygen for the engine.

Turbocharging takes less energy to create boost than supercharging. With the belt-driven supercharger system, there is no delay in making it turn faster. With turbocharging, while you can receive greater fuel efficiency and performance, you need to expend more exhaust gas to turn the turbine to turn the crankshaft to turn the other turbine to boost the power to accelerate, therefore there is a delay in this happening.

Especially during acceleration, drivers may experience a hesitation in performance, as the turbo “gets up to speed.” This is called turbo lag. Turbo lag is the time it takes for the turbine to work with the exhaust system to push air into the engine.

You can program the ECM, however, to make up for turbo lag and the time it takes for the turbine to “spool up.” By managing the electronic throttle by wire as the turbo spools up, you can partially reduce this annoyance of turbo lag.

The downside to turbocharging and supercharging is increased hardware under the hood, increased maintenance needs and increased labor time spent to repair or replace the technology.

Q: Focusing on turbochargers, what is the difference between fixed geometry turbochargers and variable geometry turbochargers?

A: Good question… Fixed geometry is considered older technology. The amount of air the turbo moves is fixed. As mentioned, the trade of energy used to energy gained is minimal, but there are limitations. And the big one is turbo lag, as discussed above.

Turbochargers with variable geometry were developed to optimize the turbo for both low and high engine speeds, thereby reducing traditional turbo lag, and improving fuel economy and engine performance. Variable geometry provides better control of that boost versus fixed geometry. By continuously varying the turbine housing’s critical area, the exhaust gas can control the speed of the turbo, boost and exhaust manifold pressure, all independent of engine speed and load.

The other term for controlling the gas into the engine is called a waste gate (i.e., flapper). This valve is controlled by a computer or engine vacuum, opening up and bypassing exhaust gas that normally would turn the turbine. By varying the amount, the turbocharger better controls the boost pressure.

Q: Benefits to turbo and superchargers? Drawbacks? Challenges?

A: For the OEM, when you improve the performance of your engine — better fuel economy and power — it is an investment. It costs more to build a turbo or supercharger on the engine. For the technician to add one… It’s not for amateurs. There is a lot of hardware to consider, when servicing or replacing.

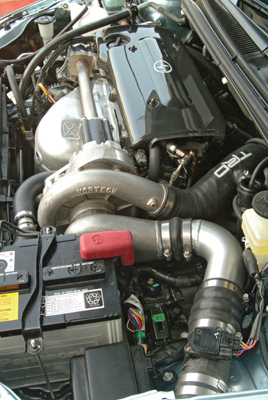

Let’s discuss installation first in the aftermarket. When installing, you should always work with a kit. And you need to make sure the kit has software that can handle the new addition to the system; a new equation of more air, more fuel.

Whenever you are pushing more air in the engine, you may push the limits on the OEM fuel injectors, fuel pump and fuel pressure regulator. There may be needed changes in software programming for the ECM/PCM. This is a huge issue. You almost always will need to adjust the ECM programming to accommodate for the super or turbocharger.

And as discussed above, you are retaining more heat under the hood. This could mean modifications to the cooling fan, radiator and the oil/lubrication system. You need to equip the system to address the hotter temperatures super and turbochargers create.

Q: Are there any technical or mathematical considerations before installing an aftermarket unit on a vehicle?

A: You need to be aware of the programming issues that come with installing or replacing a super or turbocharger.

Technicians also need to be mindful of:

• How is a super or turbo going to affect the big picture?

• Will they trip DTCs?

• Will there be issues with driveability?

• Will I need to move lines for oil? and

• Do I need to add an oil cooler and higher flow fuel injectors; install a different fuel pump (i.e., will it need a bigger pump?)

Also, the more hardware installed underhood, the more difficult it may be to “get to” or service other aspects of the vehicle. Any time you place hardware under the hood, you need to automatically allow for more labor time.

Q: What would your number one piece of advice be to technicians servicing a vehicle with a turbo or supercharger?

A: Ask questions. The only way you can make an accurate and timely diagnosis and repair is to ask questions. Was the vehicle originally normally aspirated? Does it have a turbo or super? Is that turbo or supercharger factory or add on?

Find out as much you can so there are no surprises and you can provide an accurate estimate for labor. Also, if it is an aftermarket kit, find out as much information as you can beyond the hardware. Visit the aftermarket kit provider’s website. There may be a troubleshooting guide a mouse click away. Forewarned is forearmed.

About the Author

Dave Hobbs is a Delphi Product & Service Solutions (DPSS) service trainer who serves as a hotline advisor, field engineer and technical trainer in Kokomo, IN, where he has assisted thousands of dealer and independent technicians with diagnostic problems. As an ASE Master L1 tech, Hobbs spent 15 years as an independent repair shop technician and also holds certifications for MACS and is a member of SAE.