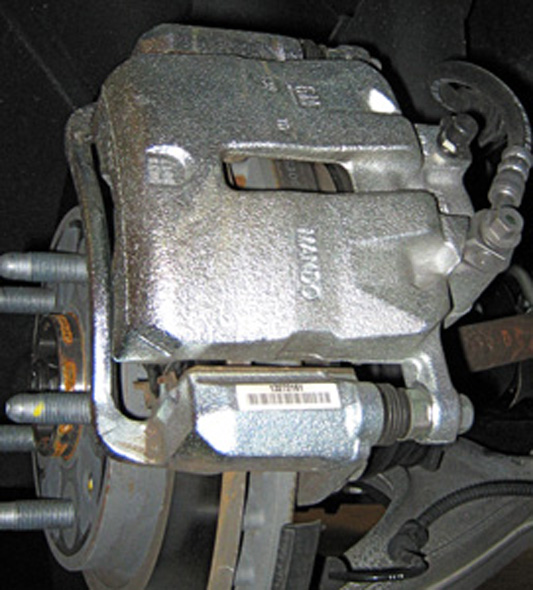

It is not that often I get a chance to examine a brake system that has less than 3,000 miles on it. On the lift, it is easy to see that the engineers put a lot of time and effort into the design of the suspension and undercar components. The brake system is very serviceable, except for the ABS modulator that is mounted behind and below the engine.

It is not that often I get a chance to examine a brake system that has less than 3,000 miles on it. On the lift, it is easy to see that the engineers put a lot of time and effort into the design of the suspension and undercar components. The brake system is very serviceable, except for the ABS modulator that is mounted behind and below the engine.

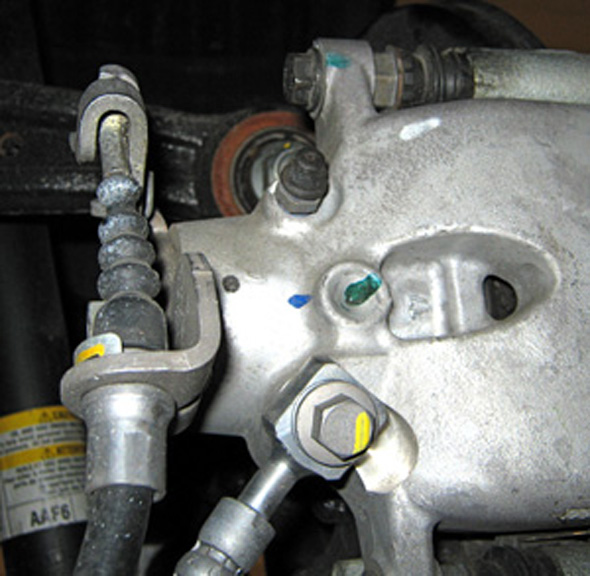

The LaCrosse is equipped with an electric parking brake. The switch is in the center console. The switch will only work if your foot is on the brake pedal. By not having a handle, e-brake turns are now impossible, but it does save space. The good news is that it adjusts itself.

The Buick LaCrosse has an electric parking brake control module that is mounted in the left rear wheel well. The unit has an electric motor, apply actuator, release actuator and temperature sensor. The electric parking brake control module also contains the electronic controls for applying and releasing the parking brake when commanded by the electric parking brake switch.