VIDEO: Heat Treated Wheel Bearing Parts

Andrew Markel discusses wheel bearing production and how heat treating makes its surfaces stronger. Sponsored by FAG, a Schaeffler brand.

VIDEO: Always Use A New Axle Nut

Andrew Markel discusses wheel hub bearing replacement, and why it is important to ensure a new axle nut is used on every job. Sponsored by FAG, a Schaeffler brand.

VIDEO: Should You Lubricate Male or Female Axle Splines?

Andrew Markel discusses whether the splines on a CV axle or wheel bearing truly need lubricated. Sponsored by FAG, a Schaeffler brand.

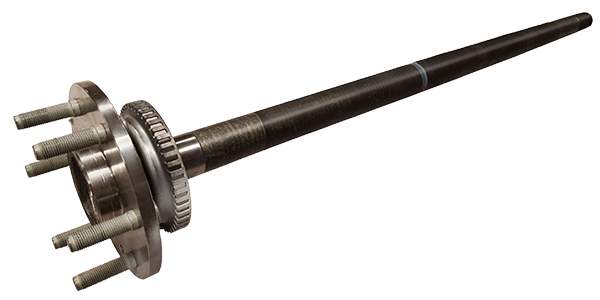

Live Axle Wheel Bearing Replacement

Replacing wheel bearings on a vehicle with a live rear axle may not be one of the most regular jobs you do, but it can be one of the most profitable. While the basics have not changed in more than 60 years, new seal materials and differential designs have added new wrinkles.

Torque Wrenches And Wheel Bearings

The torque specifications for a wheel bearing are much more exact now than in the past. This not only goes for the axle nut, but the fasteners that hold the hub unit to the suspension and lug nuts. So, what has changed? Simply put, everything has become bigger while at the same time it is getting lighter.

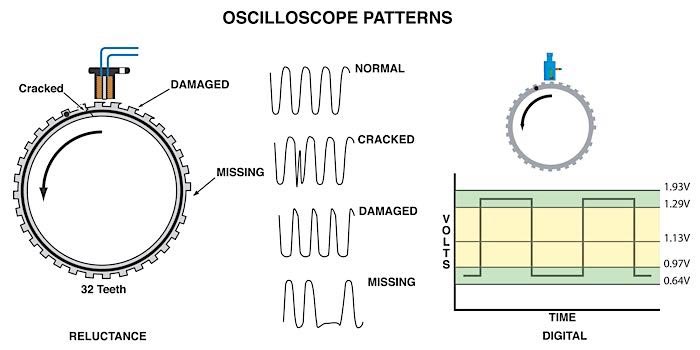

Wheel Bearings And Wheel Speed Sensors

If you are replacing a wheel bearing on a late-model vehicle, you will be dealing with a wheel speed sensor. In the past decade, wheel speed sensors have been moving from differentials, axles and knuckles to inside or on the wheel bearing or hub unit. At this location, the sensors are more accurate and often more protected from the elements. The average wheel bearing job may require a scan tool, scope or meter to verify the operation of the sensor.

VIDEO: Checking The Threading On Aluminum Knuckles

Andrew Markel discusses bearing installation on aluminum components, and why it is important to check the quality of the threads before installation. Sponsored by FAG, a Schaeffler brand.

VIDEO: Diagnosing Undercar Noises During A Test Drive

Andrew Markel shows three tips to use during a test drive to diagnose noises relating to the wheel bearings, drivetrain and other components. Sponsored by BCA Bearings.

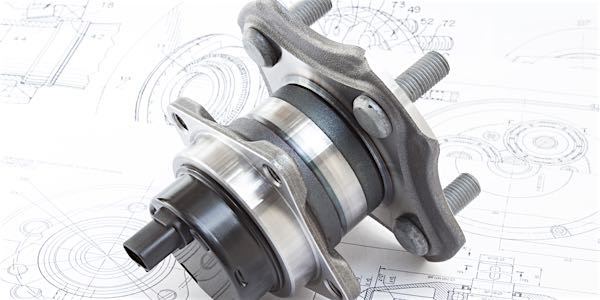

Replacing Wheel Bearing Hubs Equipped With Wheel Speed Sensors

When engineers came up with the idea of putting the wheel speed sensor (WSS) and tone ring inside a sealed wheel bearing hub assembly, it seemed like a great idea. The sealed environment would help protect the sensor and make it less vulnerable to damage or contamination from the outside.

Cleaning Bearings: Proper Procedures

While bearings may be out of sight and out of mind, they are subject to wear and damage; so, a proper cleaning can mean the difference between good performance and bearing failure. Always remember to handle any bearing with extreme care, then follow specific cleaning procedures. If a cleaning is done incorrectly, the bearing, shaft or housing may become damaged, creating a more costly repair job.

Preventing Wheel Bearing Failure

Most manufacturers recommend lubrication at 24,000 miles for the front-wheel bearings on rear-wheel drive vehicles, but bearings often are not lubricated until the brakes are replaced. That means bearings may go nearly twice as long as recommended before being relubricated, which can lead to problems.

Servicing Wheel Bearings & Wheel Speed Sensors

If you are replacing a wheel bearing on a late-model vehicle, you’ll be dealing with a wheel speed sensor. In the past decade, wheel speed sensors have been moving from differentials, axles and knuckles to inside or on the wheel bearing or hub unit. At this location, the sensors are more accurate and often more protected from the elements.