Getting a New Perspective on Ride Control Sales

Don’t give up. Surveys have shown that 50% of ride control sales occur on the second visit.

Curing Tire Vibration Woes With RFV Wheel Balancing

Most shops have the incorrect assumption that anything more than a simple balance takes too much time.

How To Diagnose NVH Complaints In Drivetrain Components

Thanks to advanced technology, modern vehicles operate with fewer noise, vibration and harshness (NVH) complaints than ever before. Consequently, when a NVH issue arises, it’s most likely caused by worn drivetrain components like universal joints, constant velocity joints or wheel bearing hub assemblies. In any case, NVH complaints can often be the most challenging to diagnose when you can’t duplicate the driving conditions under which they occur.

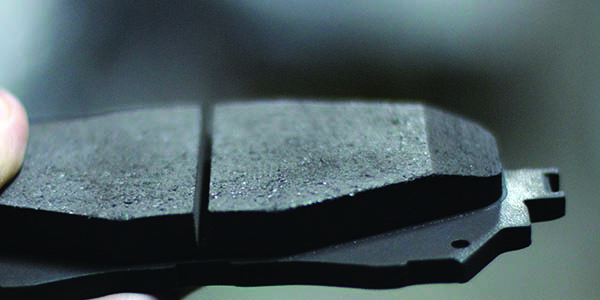

Brake Pad Chamfers, Slots And Shapes: Controlling Brake Noise

When the brake pad’s friction surface is not in harmony with the caliper and rotor, the result is usually noise. But, brake pad manufacturers have some tricks to prevent this problem or at least shift it outside of the range of human hearing.

Drive Shaft And Drivetrain Vibrations: Understanding The Order And Math

To determine if a vibration is vehicle- or engine-speed related, the easiest thing to do is slip the transmission into neutral and let the vehicle coast when the vibration is most noticeable. If the vibration continues, then the vibration is vehicle-speed related. Likewise, if the vibration subsides, the vibration is engine-speed related.

Rotor Failure: Why Rotors Crack And Make Noise

Just about every rotor is made of cast iron, but what can make or break a rotor are ingredients like carbon, silica and pearlite. Also, how a rotor is cast and cooled can determine its final properties. This is called the science of metallurgy. Ensuring that a rotor has the right metallurgy costs the manufacturer time and money. The raw materials don’t necessarily cost more, but the manufacturing process may require more expensive equipment. The energy and labor costs may also be higher.

Brake NVH: Real World Applications

First know that all brakes make noise. When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. The components are locked as a combined system that will vibrate at the combined system’s natural frequency of vibration. This is called force-coupled excitation. The driver hears

Rundown of Brake Service Chemical Applications

Penetrants for disassembly Brake system components are subjected to tremendous heat and can collect road salt, debris or other corrosive materials in the course of daily driving. Fasteners for calipers and caliper brackets are usually torqued to fairly high levels. The use of a quality penetrant at the start of brake service can ease and

Brake Noise on Pads With 50% Material Remaining

If you’re seeing an increasing number of noisy brake pads that require replacement before they reach the middle of their duty cycle, the root cause may be edge lift (partial delamination) of either the friction material or shim from the backing plate. We all know that brakes are subject to significant wear and tear during

What is Brake Noise? The Basics of Diagnosing NVH

What does your shop do when a brake noise complaint enters the service bays? Does it end up hurting productivity for the rest of the day as a technician randomly applies lubes, pastes and sprays to the brake system hoping that the problem will be at least temporarily solved? Brake systems are complex and require