VIDEO: Brake Master Cylinder Diagnostics

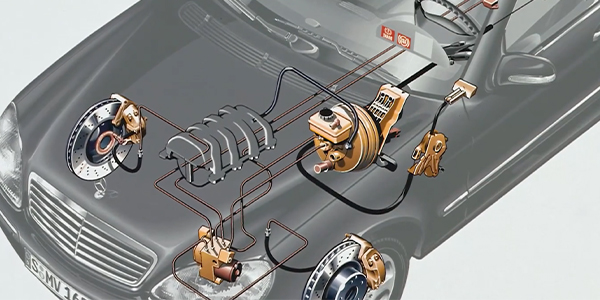

When diagnosing a brake master cylinder, you need to look at three things: Inputs, outputs & feedback. Sponsored by ADVICS.

No Pedal Condition With New Master Cylinder Installation

This tech tip will help determine if a master cylinder is defective.

ADVICS Tech Tip: Proper Master Cylinder Installation

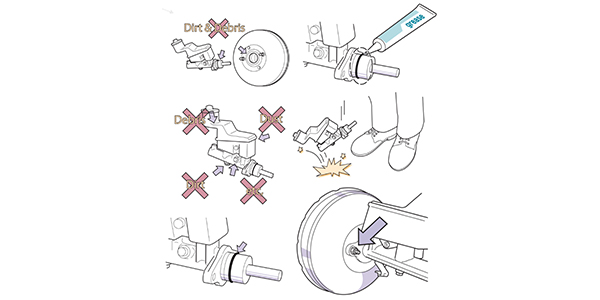

Ensure that mounting areas of the master cylinder and the pipe joints are free of damage and debris. Fluid leakage and improper hydraulic pressure may cause brake failure.

Tech Tip: Low, Sinking Or Spongy Brake Pedal

Master cylinder may be leaking fluid past the piston seals internally (by passing), not building up pressure. When diagnosing a master cylinder, keep in mind the type of seals that are used are lip cup seals. This design allows for the seal to improve as the pressure increases. Another feature of this seal is that it does not create a vacuum when the piston retracts.

Omnicraft Introduces New Master Cylinders For Non-Ford/Lincoln Vehicles

The new master cylinders are created from 100-percent new components for long life and are available now.

Failed Brake Booster Seal Causes Master Cylinder Leak

Chronic master cylinder failure due to fluid leaking past secondary seal in the master cylinder bore. A defective master cylinder pushrod seal in the power brake booster allows vacuum to draw fluid past secondary seal of the master cylinder.

Purging Air From Hydraulic Clutch Systems

Replacing a clutch bearing on a Ford Ranger, Explorer, Navajo or F-Series truck generally completes the repair with no further replacement parts needed. However, master cylinders may need to be replaced, which could result in air getting into the system. This tech tip describes a common method to remove the air from a standard hydraulic clutch system.