When a vehicle’s ABS or stability control is really needed, how well it works is directly related to the tire’s contact patch. If the tire does not have traction, any type of electronic intervention or driving skill will not bring the car back under control.

During a panic stop, weight transfers to the front tires, loads the front suspension and causes the springs to compress. How much the springs compress is influenced directly by the shocks or struts. When the springs compress, the contact patch of the tires change due to the weight and geometry of the suspension.

The rear suspension is even more interesting. When the weight loads the front tires, the rear spring expands, which makes the contact patch of the rear tire smaller. If the shock or strut is unable to control the rebound of the spring, additional weight is transferred to the front, which nosedives even more.

During a panic stop, the vehicle becomes unstable if it then needs to swerve to avoid something in its path. The front tires have all the traction while the rear tires have very little. This usually results in an oversteer or understeer condition that leads to a loss of control.

But isn’t the stability control system supposed to control this? Electronic stability control (ESC) systems use the brakes to control the attitude, weight transfer and overall traction of a vehicle in case of an emergency. The system pulses or releases the brakes individually and controls engine torque to achieve the best correction. The ESC can control the contact patch of a tire, but the system can only work with the contact patch given to it by the suspension and ride control components.

When a wheel reacts to a bump or body motion, the shock or strut is cycled. The length of the stroke doesn’t matter as much as the frequency of the cycles. Even under normal conditions on a smooth road, shocks can cycle an average of 1,750 times for every mile traveled. This can add up to almost 9 million cycles in 50,000 miles. These 9 million cycles can cause wear on the valve and seals of a shock or strut.

ESC Sensing, Action and Reaction

ESC Sensing, Action and Reaction

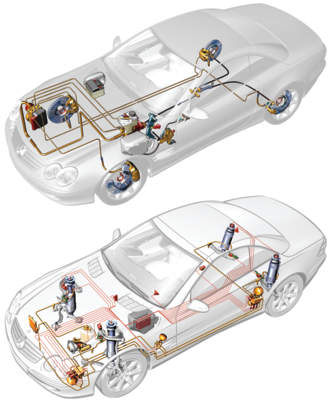

To understand an ESC, you must understand how it measures the world around it. An ESC uses yaw and accelerometer sensors to measure what the vehicle is doing. It measures what the driver is doing using pedal and steering angle sensors. The ESC interprets all of this sensor information to determine what the vehicle is doing and what the driver wants to do. More advanced systems use sensors to see what is in front of the vehicle, too.

The computer processor in the stability control takes the information and decides what is happening and what corrections should be made. After a correction is made, it measures the effectiveness of the correction and decides if any further action should be taken. This is done in real time with a very fast network and a very fast processor.

The stability control system measures the effectiveness of its correction made with the brake system. How effective the correction is depends on the condition of the contact patch of the tires. What influences the health of this contact patch is the shocks and struts.

The computer does not assign a value to the condition of the contact patch, and there are no parameters (PIDs) in the programming for most systems. The corrections and the effectiveness of those moves are measured by the sensors. The ESC system will try to make the smallest correction at first, and then it will escalate the corrections until the sensor and driver inputs indicate that the vehicle is back under control. If the traction level is optimal, it may actuate a dump or isolation valve for a small amount of time. If the contact patch is compromised due to a weak shock or strut, the correction may take a little longer.

A stability control system will never set a malfunction light if the condition of the contact patch crosses a set threshold. As the condition of the chassis and tires diminish, the corrections become less effective and more actions will be needed to bring a vehicle under control.